Boosting Generator Longevity with Metal Wear Detection Technologies

Boosting Generator Longevity with Metal Wear Detection Technologies

Understanding Generator Wear and Tear

Generators play a crucial role in power generation, providing reliable electricity for various applications. However, like any machinery, they are subject to wear and tear. This degradation can be significantly accelerated by factors such as operational hours, environmental conditions, and mai

Boosting Generator Longevity with Metal Wear Detection Technologies

Understanding Generator Wear and Tear

Generators play a crucial role in power generation, providing reliable electricity for various applications. However, like any machinery, they are subject to wear and tear. This degradation can be significantly accelerated by factors such as operational hours, environmental conditions, and maintenance practices. Recognizing the signs of wear early can prevent severe damage and extend the operational lifespan of generators.

The Importance of Monitoring Wear in Generators

Monitoring wear in generators is essential for several reasons. First, it helps in identifying potential failures before they occur, ensuring uninterrupted power supply. Second, it allows for optimized maintenance scheduling, reducing unnecessary downtime. Third, it contributes to cost savings by minimizing repair expenses and extending the life of the equipment.

Key Components Subject to Wear in Generators

- **Bearings**: Often the first components to show wear due to friction.

- **Rotor and Stator**: These parts are critical for generating electricity and can suffer from overheating.

- **Fuel Injectors**: Wear in these components can lead to inefficiency and increased fuel consumption.

Metal Wear Detection Technologies: A Game Changer

The advancement of metal wear detection technologies has revolutionized how we monitor and maintain generators. These technologies utilize various methods to detect wear, enhancing predictive maintenance and reducing unexpected failures.

Common Metal Wear Detection Technologies

Several technologies are currently employed to detect metal wear in generators, including:

1. **Vibration Analysis**: This technique assesses the vibrations emitted by the generator. Abnormal vibrations can indicate wear or damage.

2. **Acoustic Emission Monitoring**: By capturing the sound waves generated by wear particles, this technology can provide real-time data on the condition of the generator.

3. **Infrared Thermography**: This method detects heat patterns, allowing us to identify overheating components that may indicate wear.

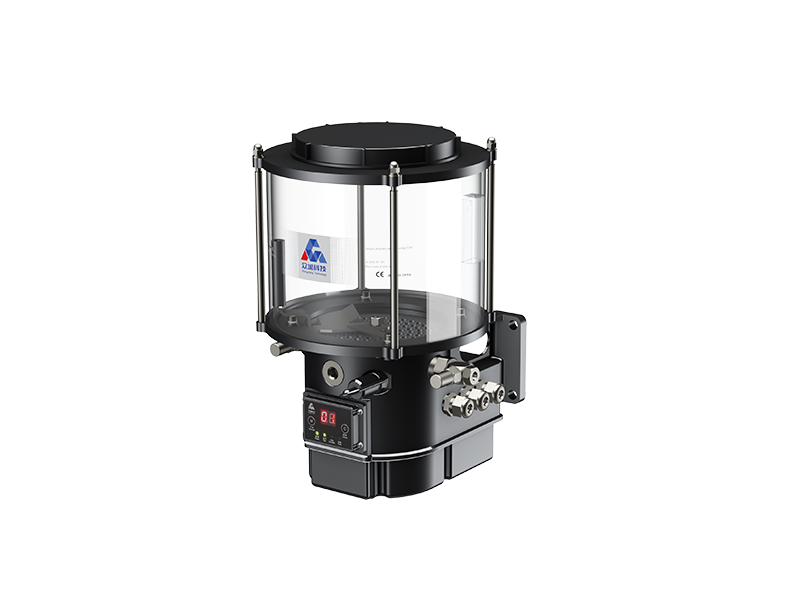

4. **Oil Analysis**: Regularly analyzing the oil for metal particles can reveal insights into the wear rates of various components.

5. **Magnetic Particle Inspection**: This non-destructive testing method helps identify surface and near-surface defects in ferromagnetic materials.

Benefits of Using Advanced Wear Detection Technologies

The integration of these technologies into maintenance routines provides numerous benefits:

- **Early Detection**: Proactive monitoring leads to early detection of potential issues.

- **Cost Efficiency**: Minimizing unplanned maintenance can significantly reduce operational costs.

- **Data-Driven Decisions**: Accurate data helps in making informed decisions regarding repairs and replacements.

Implementing Metal Wear Detection in Generator Maintenance

Integrating metal wear detection technologies into generator maintenance requires a structured approach. This includes training personnel, selecting appropriate technologies, and establishing a routine monitoring schedule.

Training and Awareness for Maintenance Personnel

To maximize the effectiveness of metal wear detection technologies, it is essential to train maintenance personnel thoroughly. Understanding how to interpret data from these technologies is crucial for timely and effective intervention.

Establishing a Routine Monitoring Schedule

Regular monitoring of wear detection technologies should be integrated into the overall maintenance schedule. This may include:

- Weekly vibration analysis checks.

- Monthly oil analysis.

- Quarterly infrared thermography scans.

Case Studies: Success Stories in Generator Longevity

Examining real-world applications of metal wear detection technologies can provide valuable insights into their effectiveness.

Case Study 1: Power Generation Facility

A major power generation facility adopted a comprehensive wear detection program. By implementing vibration analysis and oil analysis, they were able to reduce unplanned downtime by 30%, leading to significant cost savings.

Case Study 2: Industrial Manufacturing Plant

An industrial manufacturing plant faced frequent generator failures. By integrating acoustic emissions monitoring, they identified wear on bearings early, preventing catastrophic failures and extending the generator's life by several years.

Challenges in Implementing Metal Wear Detection Technologies

Despite the clear benefits, there are challenges in adopting these technologies.

Cost Implications

The initial investment in advanced detection technologies can be high. However, this cost must be weighed against the potential savings from reduced downtime and maintenance needs.

Technological Limitations

Not all wear detection technologies are suitable for every type of generator. Understanding the specific needs and limitations of your equipment is vital for successful implementation.

Future Trends in Wear Detection Technologies

As technology advances, we can expect significant improvements in metal wear detection methods. Innovations such as AI integration and IoT connectivity will streamline data collection and analysis, leading to even more precise predictive maintenance.

Artificial Intelligence in Wear Detection

AI algorithms can analyze large sets of data to predict wear patterns and failures more accurately than traditional methods.

Internet of Things (IoT) Integration

IoT devices connected to generators can provide real-time data on wear conditions, allowing for instantaneous alerts and actions.

FAQs about Metal Wear Detection Technologies

1. What is metal wear detection technology?

Metal wear detection technology includes various methods used to monitor the wear and tear of components in generators to extend their lifespan and improve efficiency.

2. How often should I perform wear detection monitoring?

It is recommended to establish a routine monitoring schedule based on the specific technology used, with weekly to quarterly checks being common.

3. What are the key benefits of using wear detection technologies?

The primary benefits include early detection of issues, cost savings through reduced downtime, and data-driven maintenance decisions.

4. Can wear detection technologies be retrofitted to existing generators?

Yes, many metal wear detection technologies can be integrated into older generator systems, enhancing their maintenance capabilities.

5. Are there any downsides to implementing metal wear detection technologies?

While there are costs associated with implementing these technologies, the long-term savings and operational efficiencies generally outweigh the initial investment.

Conclusion

Incorporating metal wear detection technologies into generator maintenance practices is essential for enhancing longevity and reducing operational costs. With a proactive approach to monitoring and maintenance, organizations can ensure the reliability of their power generation equipment. By staying informed about the latest advancements in wear detection technologies and adapting maintenance strategies accordingly, businesses can significantly extend the life of their generators, ensuring a steady and efficient power supply for years to come.