The Importance of Metal Wear Particle Sensors in Generator Equipment

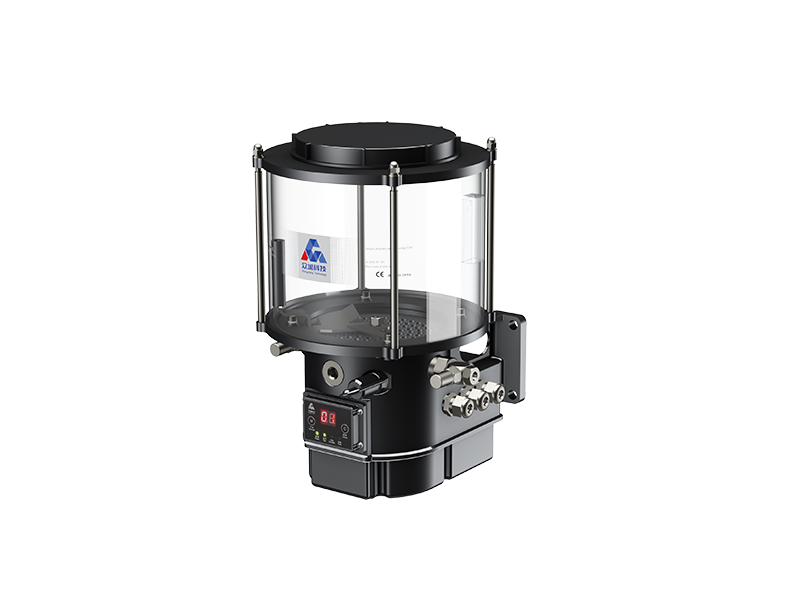

In the realm of electrical and power generation equipment, the efficiency and reliability of generators play a pivotal role in operational success. One key component contributing to this reliability is the Metal Wear Particle Sensor (MWPS). These sensors are designed to detect and monitor metal particles generated from wear and tear in machinery, providing valuable insights into the health of the

In the realm of electrical and power generation equipment, the efficiency and reliability of generators play a pivotal role in operational success. One key component contributing to this reliability is the Metal Wear Particle Sensor (MWPS). These sensors are designed to detect and monitor metal particles generated from wear and tear in machinery, providing valuable insights into the health of the equipment.

Metal wear particles are often indicative of underlying issues within mechanical systems. As components like bearings, gears, and shafts undergo normal wear, small metal fragments can be released into the lubricating oil. If left unchecked, the presence of these particles can lead to increased friction, overheating, and ultimately catastrophic failure of the equipment. This is where Metal Wear Particle Sensors come into play.

By continuously monitoring the lubricant for metal particles, these sensors offer real-time data regarding the condition of the generator components. The sensors typically employ advanced technologies, such as laser or magnetic detection, to identify and quantify particles of varying sizes. This data is crucial as it enables maintenance teams to identify potential problems before they escalate, allowing for timely interventions that can prevent costly downtime.

Moreover, the integration of MWPS into generator systems can enhance predictive maintenance strategies. By analyzing the data collected over time, engineers can establish wear patterns and trends, thus predicting when a component is likely to fail. This proactive approach not only ensures the reliability of the power generation process but also optimizes maintenance schedules, reducing unnecessary labor and parts replacement.

In addition to improving operational efficiency, Metal Wear Particle Sensors contribute to safety in power generation. By helping to identify mechanical issues early, they reduce the risk of sudden breakdowns that could lead to hazardous situations for both personnel and equipment. This aspect is especially critical in high-stakes environments where generator reliability is paramount.

Furthermore, as industries increasingly move towards automation and smart technology, the role of MWPS is becoming more significant. Integrating these sensors with data analytics platforms allows for enhanced monitoring capabilities and decision-making processes. Operators can receive alerts and insights through user-friendly interfaces, making it easier to manage maintenance and operational strategies.

In conclusion, Metal Wear Particle Sensors are an indispensable tool in the management of generator equipment within the electrical and power generation industry. By providing critical information about the health of machinery, these sensors not only aid in maintaining performance and safety but also support the shift towards more intelligent and predictive maintenance practices. As technology continues to advance, the benefits and applications of Metal Wear Particle Sensors will undoubtedly expand, further solidifying their importance in the field.

Metal wear particles are often indicative of underlying issues within mechanical systems. As components like bearings, gears, and shafts undergo normal wear, small metal fragments can be released into the lubricating oil. If left unchecked, the presence of these particles can lead to increased friction, overheating, and ultimately catastrophic failure of the equipment. This is where Metal Wear Particle Sensors come into play.

By continuously monitoring the lubricant for metal particles, these sensors offer real-time data regarding the condition of the generator components. The sensors typically employ advanced technologies, such as laser or magnetic detection, to identify and quantify particles of varying sizes. This data is crucial as it enables maintenance teams to identify potential problems before they escalate, allowing for timely interventions that can prevent costly downtime.

Moreover, the integration of MWPS into generator systems can enhance predictive maintenance strategies. By analyzing the data collected over time, engineers can establish wear patterns and trends, thus predicting when a component is likely to fail. This proactive approach not only ensures the reliability of the power generation process but also optimizes maintenance schedules, reducing unnecessary labor and parts replacement.

In addition to improving operational efficiency, Metal Wear Particle Sensors contribute to safety in power generation. By helping to identify mechanical issues early, they reduce the risk of sudden breakdowns that could lead to hazardous situations for both personnel and equipment. This aspect is especially critical in high-stakes environments where generator reliability is paramount.

Furthermore, as industries increasingly move towards automation and smart technology, the role of MWPS is becoming more significant. Integrating these sensors with data analytics platforms allows for enhanced monitoring capabilities and decision-making processes. Operators can receive alerts and insights through user-friendly interfaces, making it easier to manage maintenance and operational strategies.

In conclusion, Metal Wear Particle Sensors are an indispensable tool in the management of generator equipment within the electrical and power generation industry. By providing critical information about the health of machinery, these sensors not only aid in maintaining performance and safety but also support the shift towards more intelligent and predictive maintenance practices. As technology continues to advance, the benefits and applications of Metal Wear Particle Sensors will undoubtedly expand, further solidifying their importance in the field.