Understanding Platen High Pressure Piston Pumps: Essential Insights for Professionals

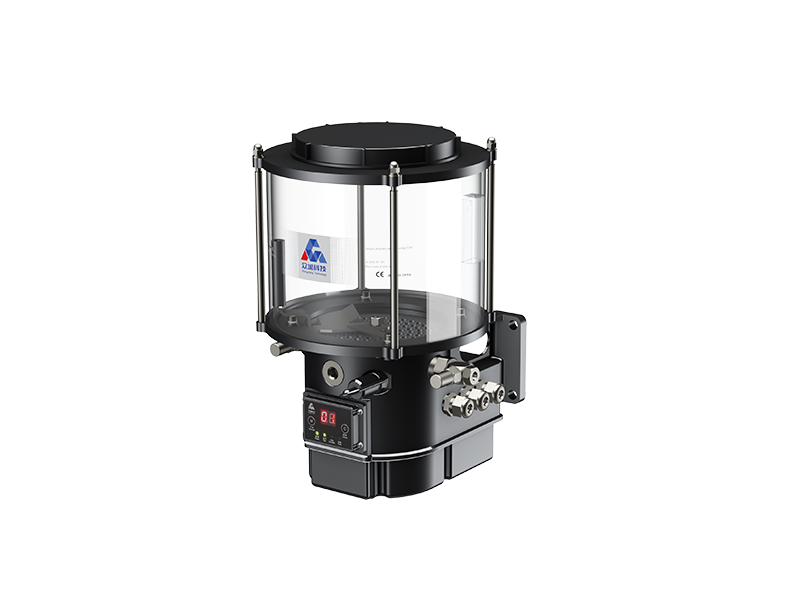

Platen High Pressure Piston Pumps are sophisticated devices designed to operate under high pressure, making them ideal for various industrial applications, particularly in the electrical and generator sectors. These pumps utilize a piston mechanism to create a high-pressure environment, effectively transferring fluids, including various types of oils and other hydraulic fluids.

One of the key adv

Platen High Pressure Piston Pumps are sophisticated devices designed to operate under high pressure, making them ideal for various industrial applications, particularly in the electrical and generator sectors. These pumps utilize a piston mechanism to create a high-pressure environment, effectively transferring fluids, including various types of oils and other hydraulic fluids.

One of the key advantages of Platen High Pressure Piston Pumps is their ability to generate consistent and reliable pressure. This is crucial in applications where precise fluid control is necessary, such as in hydraulic power systems and other machinery that require stable operation under varying conditions. The high efficiency of these pumps ensures minimal energy loss during operation, which is vital for maintaining optimal performance in generator systems.

The construction of Platen High Pressure Piston Pumps typically involves durable materials that can withstand the stresses associated with high-pressure applications. This durability not only enhances the longevity of the pump but also reduces the frequency of maintenance interventions, which can be a significant cost-saving factor for businesses. Furthermore, the design often allows for easy integration into existing systems, making retrofitting a more straightforward process for professionals looking to upgrade their equipment.

In terms of applications, these pumps are commonly found in various industries, including oil and gas, water treatment, and manufacturing processes that involve hydraulic systems. In the electrical and generator industry, they play a crucial role in cooling systems, lubrication systems, and other auxiliary functions that support the main generator operation.

It's also important to note that the performance of a Platen High Pressure Piston Pump can be influenced by several factors, including fluid viscosity, temperature, and the specific design of the pump itself. Therefore, professionals must carefully consider these variables when selecting a pump for their application to ensure optimal performance and reliability.

Additionally, when operating a Platen High Pressure Piston Pump, it is essential to adhere to safety guidelines and operational protocols. High-pressure systems can pose risks if not handled correctly, so personnel should have the necessary training and experience to manage these systems safely.

In conclusion, Platen High Pressure Piston Pumps are integral to efficient fluid transfer systems within the electrical and generator sectors. Understanding their operation, advantages, and applications can empower professionals to make informed decisions, ensuring enhanced performance and reliability in their operations.

One of the key advantages of Platen High Pressure Piston Pumps is their ability to generate consistent and reliable pressure. This is crucial in applications where precise fluid control is necessary, such as in hydraulic power systems and other machinery that require stable operation under varying conditions. The high efficiency of these pumps ensures minimal energy loss during operation, which is vital for maintaining optimal performance in generator systems.

The construction of Platen High Pressure Piston Pumps typically involves durable materials that can withstand the stresses associated with high-pressure applications. This durability not only enhances the longevity of the pump but also reduces the frequency of maintenance interventions, which can be a significant cost-saving factor for businesses. Furthermore, the design often allows for easy integration into existing systems, making retrofitting a more straightforward process for professionals looking to upgrade their equipment.

In terms of applications, these pumps are commonly found in various industries, including oil and gas, water treatment, and manufacturing processes that involve hydraulic systems. In the electrical and generator industry, they play a crucial role in cooling systems, lubrication systems, and other auxiliary functions that support the main generator operation.

It's also important to note that the performance of a Platen High Pressure Piston Pump can be influenced by several factors, including fluid viscosity, temperature, and the specific design of the pump itself. Therefore, professionals must carefully consider these variables when selecting a pump for their application to ensure optimal performance and reliability.

Additionally, when operating a Platen High Pressure Piston Pump, it is essential to adhere to safety guidelines and operational protocols. High-pressure systems can pose risks if not handled correctly, so personnel should have the necessary training and experience to manage these systems safely.

In conclusion, Platen High Pressure Piston Pumps are integral to efficient fluid transfer systems within the electrical and generator sectors. Understanding their operation, advantages, and applications can empower professionals to make informed decisions, ensuring enhanced performance and reliability in their operations.