The Role of Platen High Pressure Piston Pumps in Sustainable Energy Solutions

The Role of Platen High Pressure Piston Pumps in Sustainable Energy Solutions

Table of Contents

Introduction: Understanding Sustainable Energy Solutions

What Are Platen High Pressure Piston Pumps?

Operational Principles of Platen High Pressure Piston Pumps

Applications in Sustainable Energy Solutions

Advantages of Using Platen High Pressure Piston Pumps

Environmental Impac

The Role of Platen High Pressure Piston Pumps in Sustainable Energy Solutions

Table of Contents

- Introduction: Understanding Sustainable Energy Solutions

- What Are Platen High Pressure Piston Pumps?

- Operational Principles of Platen High Pressure Piston Pumps

- Applications in Sustainable Energy Solutions

- Advantages of Using Platen High Pressure Piston Pumps

- Environmental Impact and Sustainability

- Future Trends in Pump Technology and Sustainability

- Conclusion: Embracing Sustainable Practices with Advanced Pump Technology

- FAQs

Introduction: Understanding Sustainable Energy Solutions

In the quest for **sustainable energy solutions**, the focus has shifted towards technologies that not only enhance efficiency but also minimize environmental impact. Among these technologies, **platen high pressure piston pumps** stand out as crucial components in various energy systems. By facilitating the movement of fluids at high pressure, these pumps play a significant role in the efficiency and effectiveness of energy production processes. This article delves into the intricacies of platen high pressure piston pumps and their essential contributions to sustainable energy.

What Are Platen High Pressure Piston Pumps?

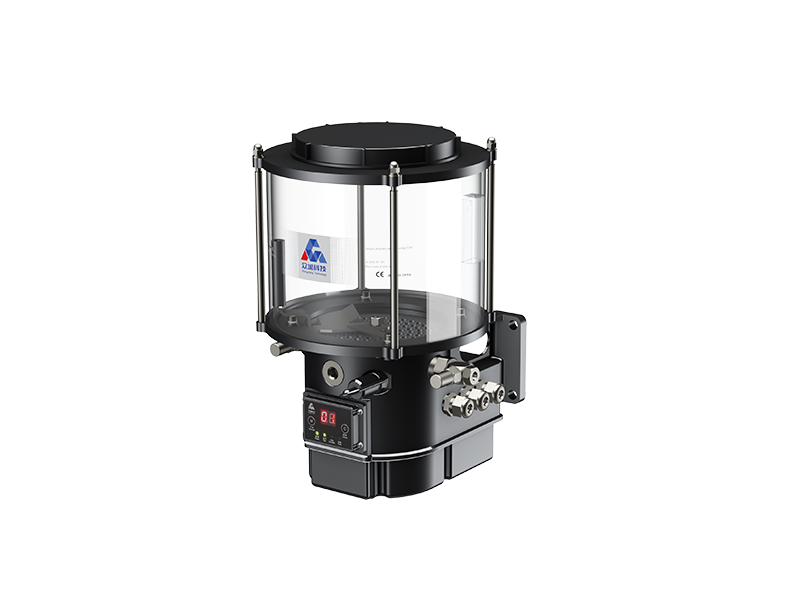

Platen high pressure piston pumps are specialized devices designed to transport liquids by converting mechanical energy into hydraulic energy. These pumps utilize pistons that move within a cylinder, creating a high-pressure environment that allows them to efficiently move fluids. With capabilities to handle various types of fluids, including those that are viscous or contain particulates, these pumps are widely used in industries ranging from **oil and gas** to **renewable energy** sectors.

Key Features of Platen High Pressure Piston Pumps

- **Efficiency**: Designed for high performance, these pumps minimize energy consumption while maximizing output.

- **Durability**: Constructed from robust materials, they can withstand harsh conditions, making them suitable for demanding applications.

- **Versatility**: They can handle a variety of fluids, including water, oils, and chemicals, broadening their application scope.

- **Compact Design**: Their compact size enables easier integration into existing systems without requiring significant modifications.

Operational Principles of Platen High Pressure Piston Pumps

The operation of platen high pressure piston pumps is based on the principles of positive displacement. When the piston moves within the cylinder, it creates a vacuum that draws fluid into the pump. Upon reversing direction, the piston compresses the fluid and forces it out at high pressure. This cyclical motion ensures a steady flow, making these pumps highly reliable for various applications.

Components of Platen High Pressure Piston Pumps

Understanding the operational components of these pumps is essential:

- **Piston**: The critical component responsible for creating pressure.

- **Cylinder**: Houses the piston and provides the necessary environment for fluid movement.

- **Inlet and Outlet Valves**: Regulate the intake and discharge of fluid, ensuring efficient operation.

- **Drive Mechanism**: Often powered by electric motors or hydraulic systems, it provides the energy required for the piston movement.

Applications in Sustainable Energy Solutions

Platen high pressure piston pumps are utilized across various sectors within sustainable energy solutions. Their ability to efficiently handle fluids makes them ideal for processes such as **hydraulic fracturing**, **geothermal energy extraction**, and **biomass energy production**.

Hydraulic Fracturing

In the oil and gas industry, hydraulic fracturing relies heavily on these pumps to inject fluids at high pressure into rock formations. This process enhances oil and gas recovery while minimizing waste.

Geothermal Energy Extraction

Geothermal plants use these pumps to circulate water through geothermal reservoirs, where heat is extracted to generate steam, driving turbines for electricity production.

Biomass Energy Production

In the biomass sector, these pumps facilitate the transportation of organic materials to anaerobic digesters, thereby supporting the production of renewable biogas.

Advantages of Using Platen High Pressure Piston Pumps

The advantages of incorporating platen high pressure piston pumps into energy systems are numerous:

Increased Efficiency

By maximizing fluid movement with minimal energy input, these pumps significantly enhance the overall efficiency of energy systems.

Reduced Environmental Impact

Their precise control over fluid movement allows for reduced waste and lower emissions, contributing to eco-friendly practices.

Cost-Effectiveness

The durability and reliability of these pumps lead to lower maintenance costs and reduced downtime, providing a significant return on investment.

Adaptability to Renewable Energy Sources

As the demand for renewable energy continues to rise, platen pumps can be adapted for various applications, making them vital in transitioning to greener energy practices.

Environmental Impact and Sustainability

The integration of platen high pressure piston pumps in sustainable energy systems has a profound environmental impact. These pumps not only aid in reducing emissions and waste but also optimize resource use.

Energy Efficiency and Waste Reduction

By facilitating efficient fluid management, these pumps help in minimizing energy consumption and waste generation, aligning with sustainability goals.

Supporting Renewable Energy Initiatives

Their versatility allows for greater implementation in renewable projects, enhancing energy production from natural resources while reducing reliance on fossil fuels.

Future Trends in Pump Technology and Sustainability

As technology continues to evolve, so too does the role of platen high pressure piston pumps in sustainable energy solutions. Future trends may include:

Smart Pump Technology

The incorporation of IoT and smart sensors will enable real-time monitoring and optimization of pump performance, leading to enhanced efficiency.

Sustainable Materials

The development of pumps using eco-friendly materials will contribute to reducing the carbon footprint of pump manufacturing and operation.

Integration with Renewable Sources

We can expect greater integration of these pumps with emerging renewable energy technologies, further advancing sustainable practices in energy production.

Conclusion: Embracing Sustainable Practices with Advanced Pump Technology

Platen high pressure piston pumps play an invaluable role in advancing sustainable energy solutions. Their efficiency, adaptability, and minimal environmental impact make them a cornerstone of modern energy systems. By embracing this technology, industries can not only enhance their operational effectiveness but also contribute to a sustainable future. As we continue to innovate and integrate these pumps into various energy sectors, the journey towards a greener planet becomes increasingly achievable.

FAQs

1. What are the main benefits of using platen high pressure piston pumps in energy systems?

The primary benefits include increased efficiency, cost-effectiveness, durability, and reduced environmental impact.

2. How do platen high pressure piston pumps contribute to renewable energy?

These pumps facilitate fluid movement in various renewable energy applications, enhancing efficiency and optimizing resource use.

3. What industries benefit from platen high pressure piston pumps?

Industries such as oil and gas, geothermal energy, biomass energy, and hydraulic fracturing benefit significantly from these pumps.

4. Are platen high pressure piston pumps environmentally friendly?

Yes, they are designed to minimize waste and emissions, making them a sustainable choice for energy systems.

5. What are the future trends for platen high pressure piston pumps?

Future trends include the development of smart pump technology, the use of sustainable materials, and greater integration with renewable energy sources.