Construction Machinery

Application Environment

Inaccurate lubrication: Manual filling is prone to miss lubrication points, and the amount of grease is difficult to control, resulting in friction or over-lubrication of the friction pair.

Poor environmental adaptability: Under harsh working conditions such as high temperature, low temperature, and dust, traditional grease is prone to failure or contamination, aggravating component wear.

High maintenance cost: More than 60% of equipment failures are caused by poor lubrication, and frequent shutdowns for maintenance increase operating costs.

High labor intensity: Manual lubrication requires frequent operations, especially in hidden parts such as the chassis, which is inefficient and poses safety hazards.

Solution

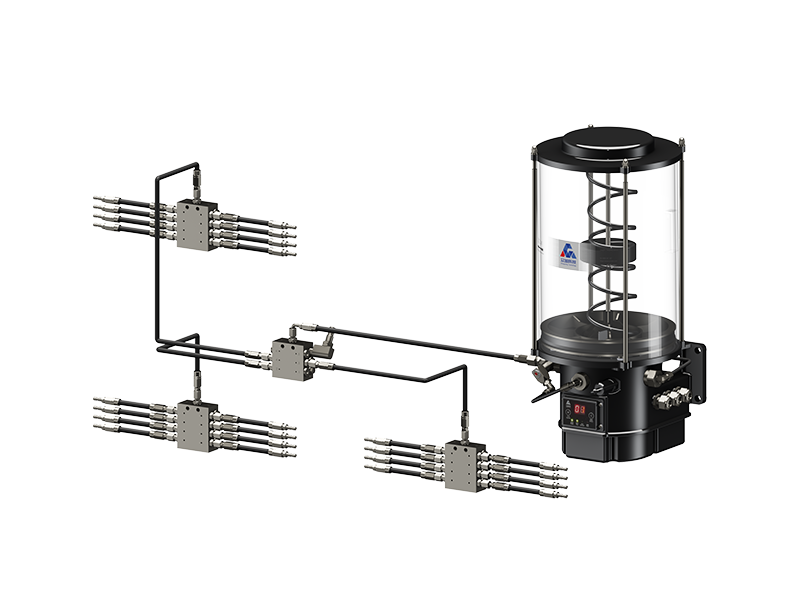

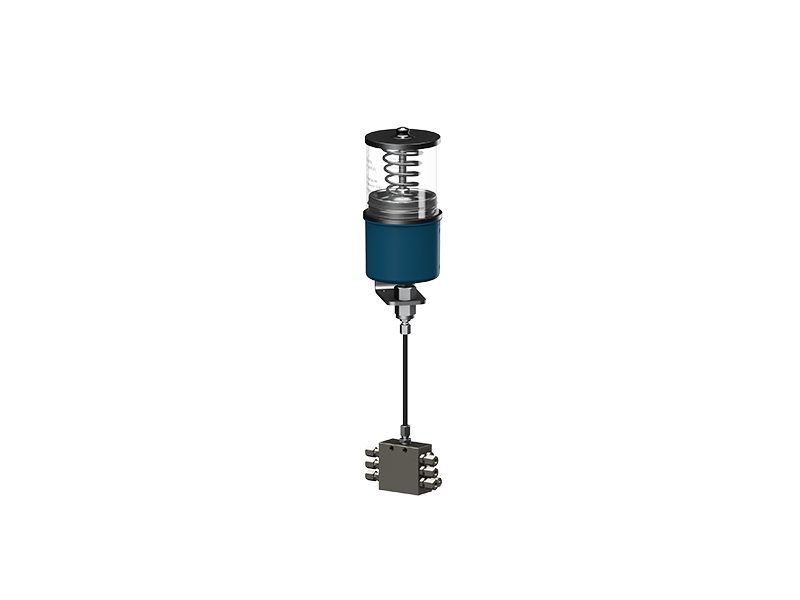

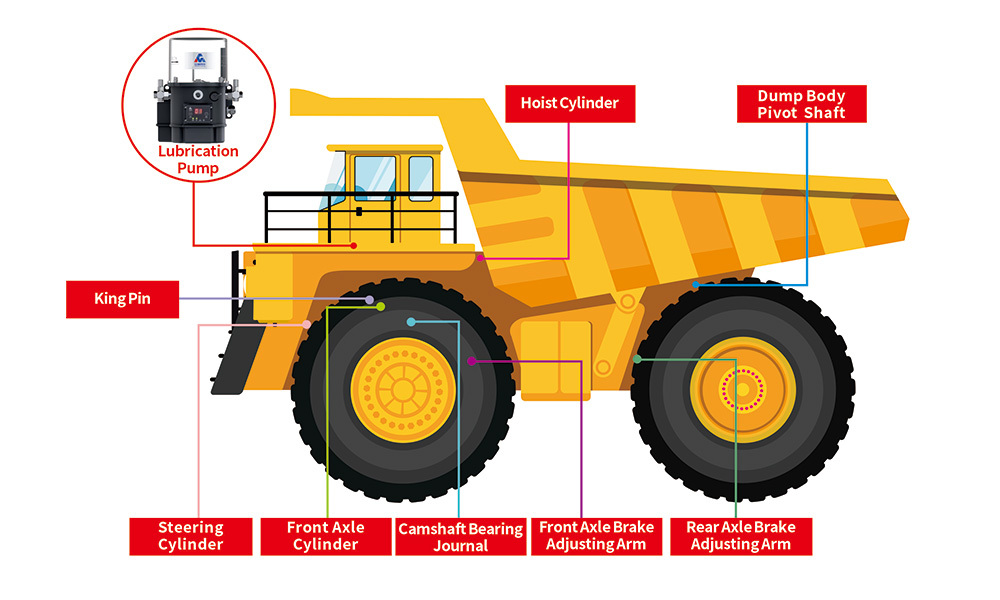

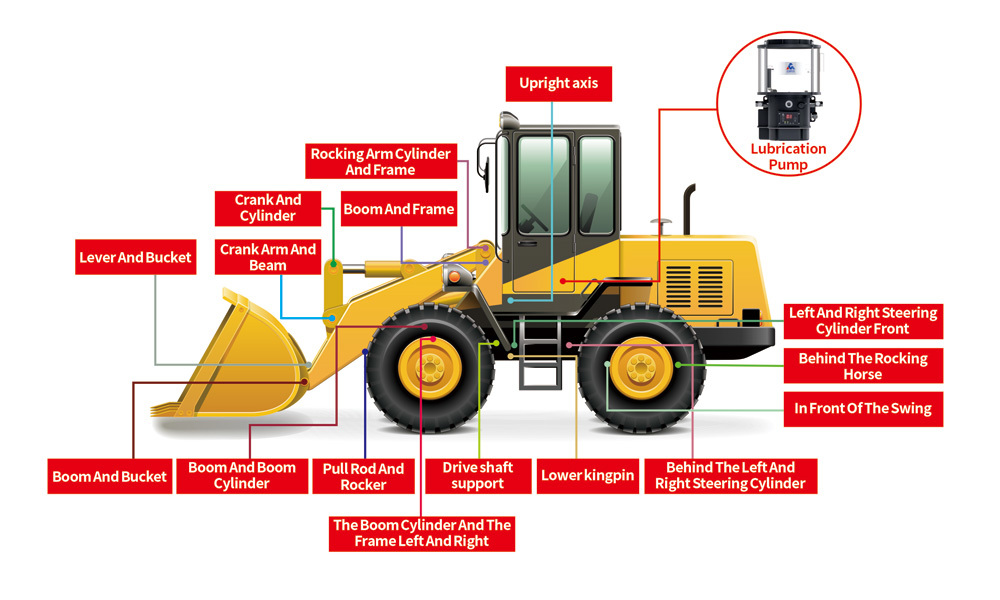

The centralized lubrication system replaces the traditional manual dispersed lubrication through the automatic lubrication method of timing, quantity, fixed point and sequence, solving the problems of wear, high energy consumption and high maintenance cost caused by poor lubrication of construction machinery. The system consists of a lubrication pump, distributor, controller, pipeline, etc., and realizes precise grease supply through progressive or single-line distributors, which is suitable for harsh working conditions such as heavy load, high temperature and high cold. For example, the progressive system drives the distributor piston to move sequentially through pressure to ensure that each lubrication point is supplied with grease on demand, and monitors the lubrication status in real time through sensors.

High performance adaptation: ZC7X and ZC5X support extreme low temperatures of -40 ℃ and high pressure output of 30MPa, meeting the needs of high-altitude regions.

-Intelligent management: Integrated CAN module, can be connected to the Internet of Vehicles for remote monitoring; Equipped with IP67 protection level, it has outstanding waterproof and dustproof capabilities.

Long life design: using brushless synchronous motor, with a service life of up to 12 years; The patented stirring rod design avoids emptying and ensures stable grease supply.

-Energy saving and environmental protection: Quantitative fat supply reduces oil waste (saving 80% of usage) and lowers environmental pollution.

Run point plan

Excavator

Mining Truck

loader

Adaptive Products

Provide safe and reliable lubrication solutions for global customers

Related Cases

Provide safe and reliable lubrication solutions for global customers

Get Exclusive Customized Solutions

Would you like to know more about our products? Please fill out the form. Alternatively, you can send us a detailed list of requirements and we will get back to you within 1 working day.