Wind Power System

Industry pain points

1. Traditional manual lubrication has problems such as uneven grease injection and irregular cycles, and high-altitude operations are risky, especially in offshore wind farms, where poor accessibility leads to limited refueling time windows.

2. The amount of oil injected by traditional manual lubrication is difficult to control, and the grease nozzle leaks, and dust and other dirt are easily brought into the friction pair, aggravating wear.

3. Traditional manual lubrication has low efficiency and poor reliability, and also causes a large amount of grease waste.

Solution

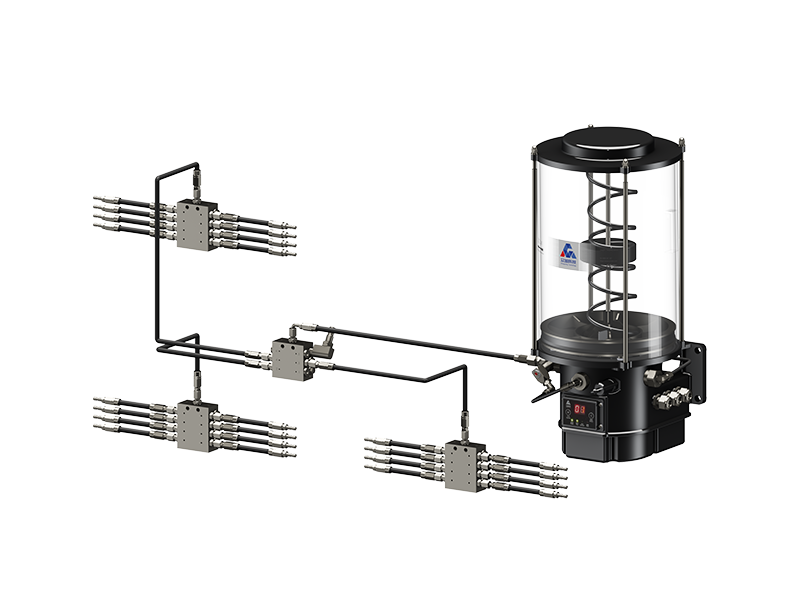

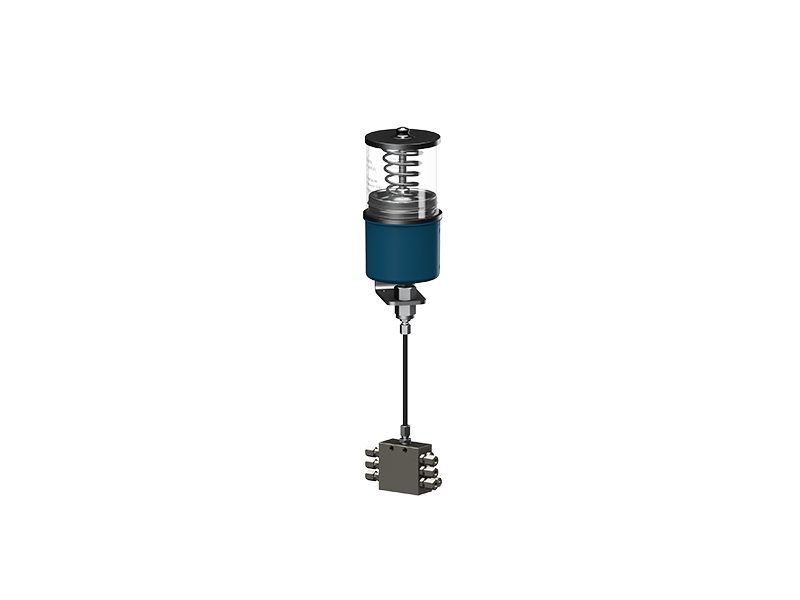

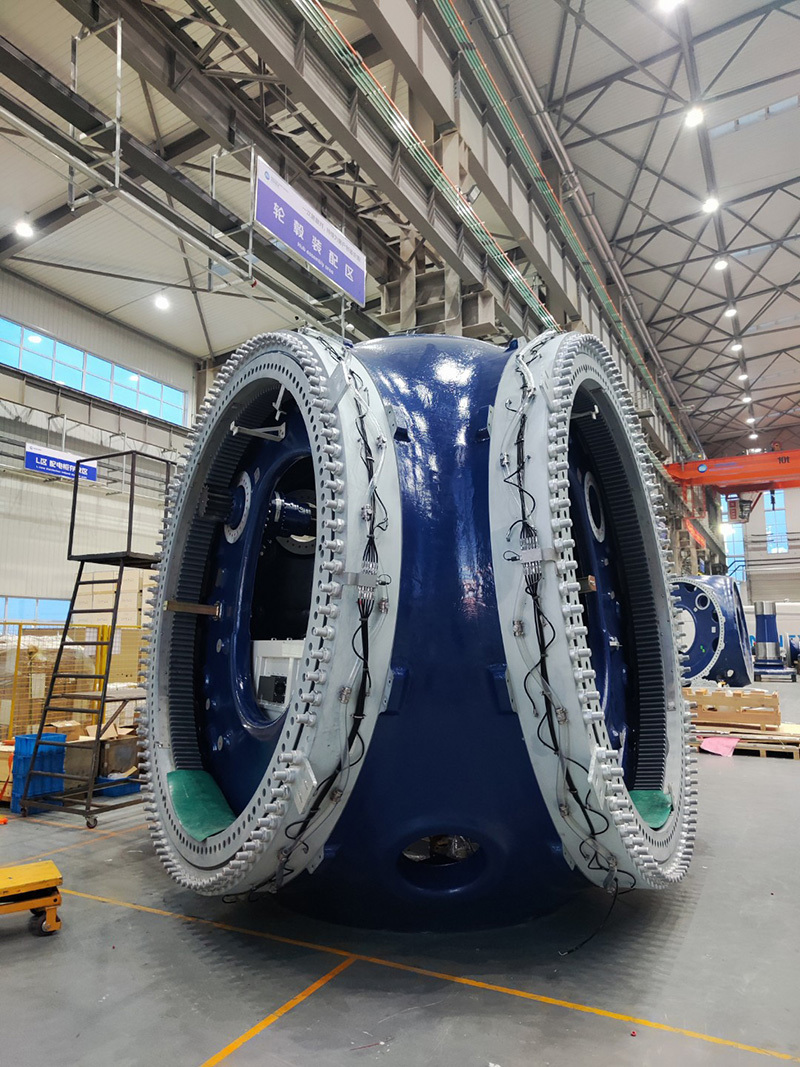

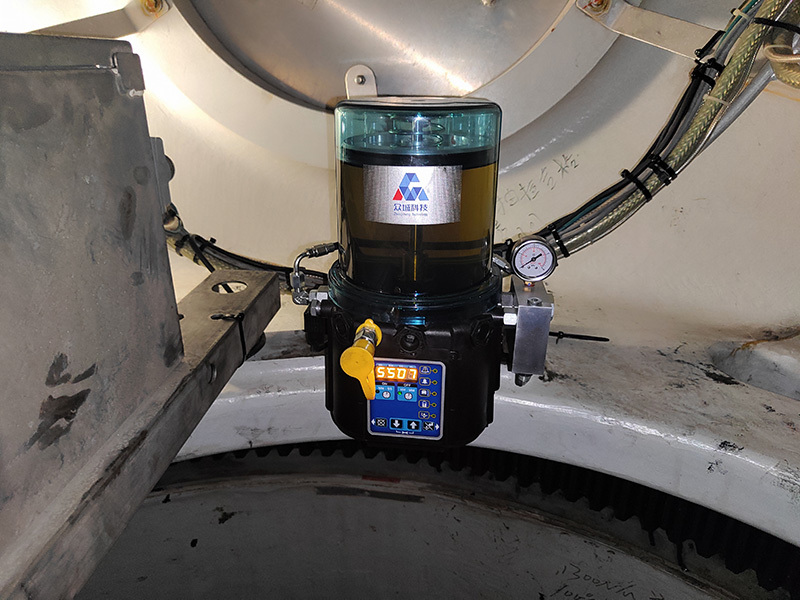

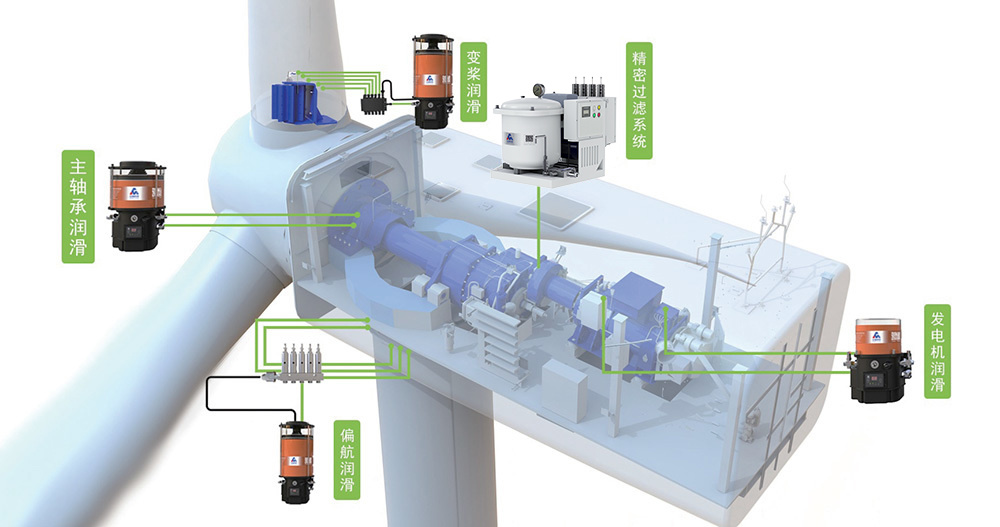

Zhongcheng Technology's technical team conducted on-site research on unit configuration, customer needs, wind farm environmental characteristics, etc., and made targeted centralized lubrication system solutions for wind turbine main shafts and generators. It launched special lubrication equipment for wind power and online oil monitoring technology to help wind farms improve power generation efficiency and reduce operation and maintenance pressure.

Run point plan

Adaptive Products

Provide safe and reliable lubrication solutions for global customers

Related Cases

Provide safe and reliable lubrication solutions for global customers

Get Exclusive Customized Solutions

Would you like to know more about our products? Please fill out the form. Alternatively, you can send us a detailed list of requirements and we will get back to you within 1 working day.