Exploring the Longevity of Platen High Pressure Piston Pumps in Harsh Environments

Exploring the Longevity of Platen High Pressure Piston Pumps in Harsh Environments

Table of Contents

1. Introduction to Platen High Pressure Piston Pumps

2. Understanding the Mechanism of Platen Pumps

3. Why Longevity Matters: Impacts on Efficiency and Cost

3.1. The Role of Reliability in Harsh Environments

3.2. Economic Benefits of Durable Pumps

4. Key Factors Affecting Longevity

4.1. Material Se

Exploring the Longevity of Platen High Pressure Piston Pumps in Harsh Environments

Table of Contents

1. Introduction to Platen High Pressure Piston Pumps

2. Understanding the Mechanism of Platen Pumps

3. Why Longevity Matters: Impacts on Efficiency and Cost

3.1. The Role of Reliability in Harsh Environments

3.2. Economic Benefits of Durable Pumps

4. Key Factors Affecting Longevity

4.1. Material Selection and Engineering

4.2. Maintenance Strategies for Extended Lifespan

4.3. Operating Conditions in Extreme Environments

5. Real-World Applications of Platen High Pressure Piston Pumps

5.1. Oil and Gas Industry

5.2. Mining Operations

5.3. Water Treatment Facilities

6. Innovations in Pump Technology

6.1. Smart Monitoring Systems

6.2. Advanced Seal Designs

7. Best Practices for Maintaining Longevity

7.1. Routine Inspection and Monitoring

7.2. Proper Installation Techniques

8. Frequently Asked Questions (FAQs)

9. Conclusion

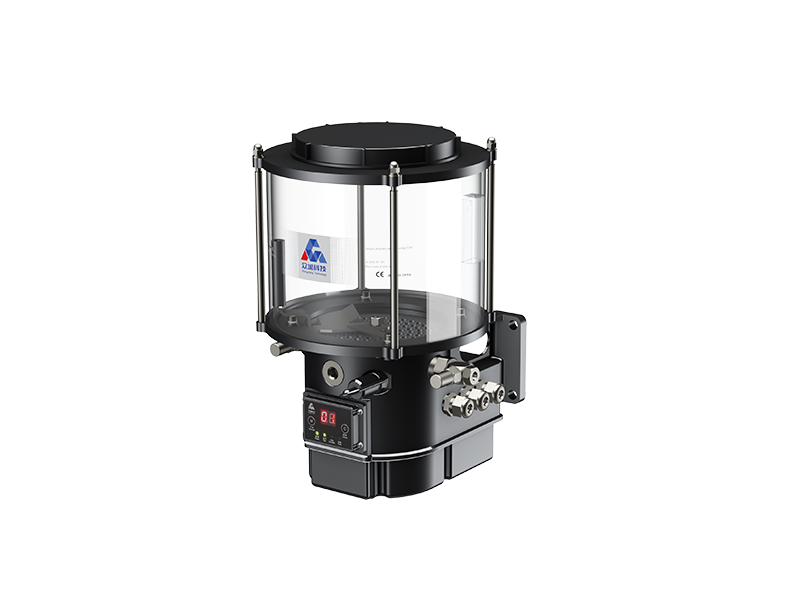

1. Introduction to Platen High Pressure Piston Pumps

Platen high pressure piston pumps are critical components in various industrial applications, known for their ability to manage high pressures with remarkable efficiency. A combination of advanced engineering and robust design makes these pumps suitable for harsh environments where regular maintenance may be challenging. Understanding the longevity of these pumps is essential for industries that rely on continuous operation, including oil and gas, mining, and water treatment.

2. Understanding the Mechanism of Platen Pumps

Platen high pressure piston pumps operate through a well-defined mechanism that involves several key components. At their core, they consist of pistons that move back and forth within a cylinder, creating pressure that moves fluids through a system. The design often incorporates a platen, which serves as a base for the pistons. This configuration allows for efficient energy transfer and pressure generation, making these pumps highly effective in demanding environments.

3. Why Longevity Matters: Impacts on Efficiency and Cost

The longevity of platen high pressure piston pumps directly influences operational efficiency and overall costs. When these pumps function reliably over extended periods, they contribute to:

3.1. The Role of Reliability in Harsh Environments

In harsh environments, where conditions can be unpredictable, having a reliable pump is crucial. A failure can lead to significant downtime, affecting production schedules and financial performance. Therefore, understanding how to enhance the reliability of these pumps is vital.

3.2. Economic Benefits of Durable Pumps

Investing in durable pumps can lead to substantial cost savings. Fewer breakdowns result in lower maintenance costs and reduced need for replacements, thus enhancing the return on investment (ROI) over time. Moreover, companies can allocate resources more effectively when they are not frequently replacing equipment.

4. Key Factors Affecting Longevity

Several factors contribute to the longevity of platen high pressure piston pumps, making it essential for operators to understand and manage these aspects effectively.

4.1. Material Selection and Engineering

The materials used in the construction of platen pumps significantly impact their durability. High-quality metals and composites can resist wear and corrosion, essential attributes when pumps are used in harsh conditions. Engineering design also plays a crucial role in ensuring that the pump can withstand the mechanical stresses encountered during operation.

4.2. Maintenance Strategies for Extended Lifespan

Regular maintenance is a critical factor in prolonging the life of platen pumps. Implementing robust maintenance schedules that include routine inspections, lubrication, and timely replacement of worn parts can dramatically improve their longevity.

4.3. Operating Conditions in Extreme Environments

The specific conditions in which pumps operate—such as temperature extremes, corrosive environments, and the presence of particulates—can substantially affect their lifespan. Understanding these factors allows operators to make informed choices regarding pump specifications and maintenance practices.

5. Real-World Applications of Platen High Pressure Piston Pumps

Platen high pressure piston pumps find applications in various industries, each presenting unique challenges and requirements.

5.1. Oil and Gas Industry

In the oil and gas sector, these pumps are employed for drilling and extraction processes. The harsh conditions, including high pressure and corrosive fluids, make the longevity of the pumps paramount for operational efficiency and safety.

5.2. Mining Operations

Mining operations often utilize these pumps for transporting slurries and other fluids. The abrasive nature of the materials can lead to rapid wear, necessitating durable pump designs that can withstand such challenging environments.

5.3. Water Treatment Facilities

Water treatment facilities rely on platen pumps to move water through various filtration and treatment stages. Ensuring the longevity of these pumps guarantees consistent water quality and operational reliability.

6. Innovations in Pump Technology

Technological advancements continue to enhance the performance and longevity of platen high pressure piston pumps.

6.1. Smart Monitoring Systems

The integration of smart monitoring systems allows for real-time assessment of pump performance and condition. These systems can predict failures before they occur, enabling proactive maintenance and extending the operational life of the pumps.

6.2. Advanced Seal Designs

Innovations in seal design have significantly improved the resistance of pumps to leaks and contamination. Enhanced seals can withstand extreme pressures and temperatures, contributing to overall durability.

7. Best Practices for Maintaining Longevity

To maximize the lifespan of platen high pressure piston pumps, it is essential to adopt best maintenance practices.

7.1. Routine Inspection and Monitoring

Conducting regular inspections allows for the early identification of potential issues. Monitoring key performance indicators can help operators understand when maintenance is required.

7.2. Proper Installation Techniques

Ensuring that pumps are installed correctly is vital for their longevity. Misalignment and improper mounting can lead to premature wear and failure, so following manufacturer guidelines is crucial.

8. Frequently Asked Questions (FAQs)

What are platen high pressure piston pumps used for?

Platen high pressure piston pumps are used in various applications, including oil and gas extraction, mining, and water treatment, where high pressure and durability are required.

How can I extend the lifespan of my platen pump?

To extend the lifespan of your platen pump, implement regular maintenance schedules, use high-quality materials, and ensure proper installation techniques.

What materials are best for high pressure piston pumps?

Materials such as stainless steel, chrome-plated alloys, and high-performance plastics are ideal for high pressure piston pumps due to their resistance to wear and corrosion.

How does operating temperature affect pump longevity?

Operating at extreme temperatures can lead to material degradation and increased wear, negatively impacting the longevity of pumps. It is important to select pumps rated for the specific temperature conditions.

Can smart technologies help in maintaining pumps?

Yes, smart technologies enable real-time monitoring and predictive maintenance, allowing for timely interventions that can prolong the lifespan of pumps.

9. Conclusion

The longevity of platen high pressure piston pumps in harsh environments is influenced by various factors, including material selection, maintenance practices, and operating conditions. By understanding these elements and implementing best practices, industries can ensure that their pumps operate efficiently and reliably over extended periods. Investing in durable pump technology and innovative solutions will not only enhance operational efficiency but also result in significant cost savings, making it essential for businesses to prioritize longevity in their pumping solutions.