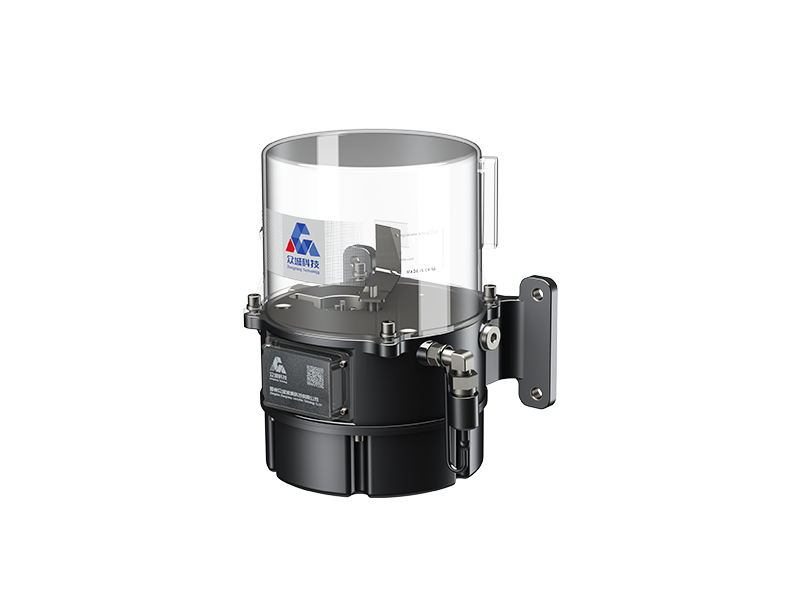

Lubrication Pump for Efficient and Reliable Industrial Lubrication

Lubrication Pump plays a vital role in modern industrial systems by ensuring consistent, accurate, and efficient delivery of lubricants to critical mechanical components. As industrial equipment becomes more complex and operates under higher loads, speeds, and temperatures, reliable lubrication is no longer optional but essential for maintaining performance, safety, and long-term stability. A high-quality lubrication pump is designed to support continuous operation, reduce mechanical stress, and extend the service life of machinery across a wide range of industries.

At its core, a lubrication pump functions as the central control unit of an automated lubrication system. It precisely supplies oil or grease to bearings, gears, chains, guide rails, and other moving parts according to predefined intervals and volumes. Compared with manual lubrication, a lubrication pump eliminates human error, ensures uniform lubricant distribution, and maintains optimal lubrication conditions even in harsh or hard-to-reach environments. This systematic approach significantly improves equipment reliability and operational consistency.

One of the key advantages of a modern lubrication pump is its high precision and stability. Advanced pumping mechanisms and flow control technology enable accurate dosing, preventing both under-lubrication and over-lubrication. Under-lubrication often leads to accelerated wear and premature component failure, while over-lubrication can cause energy loss, seal damage, and environmental contamination. By delivering the right amount of lubricant at the right time, a lubrication pump achieves a balanced lubrication strategy that protects equipment while optimizing resource usage.

Durability and adaptability are also major strengths of industrial lubrication pump systems. Manufactured using high-quality materials and engineered for demanding environments, these pumps can operate reliably under extreme temperatures, high pressure, dust, vibration, and continuous-duty conditions. Whether integrated into CNC machines, steel processing lines, injection molding equipment, mining machinery, or wind power systems, a lubrication pump maintains consistent performance and minimizes the risk of unexpected downtime.

From an operational perspective, a lubrication pump directly contributes to cost reduction and productivity improvement. Effective lubrication reduces friction and wear, which lowers energy consumption and slows component degradation. This results in fewer breakdowns, reduced maintenance frequency, and lower spare parts costs. For production facilities, this means longer machine uptime, stable output quality, and improved overall equipment effectiveness. A well-designed lubrication pump system quickly pays for itself by preventing costly failures and extending maintenance intervals.

In real-world applications, many manufacturers have successfully enhanced equipment performance by upgrading to automated lubrication pump solutions. For example, a heavy machinery plant faced frequent bearing failures and unplanned shutdowns due to inconsistent manual lubrication. After installing a centralized lubrication pump system, lubricant supply became precise and continuous, bearing temperatures dropped noticeably, and maintenance-related downtime was reduced by more than 30 percent. This improvement not only increased production efficiency but also significantly lowered long-term operating costs.

Another typical case can be found in high-speed manufacturing lines, where equipment operates around the clock with minimal tolerance for interruption. In such environments, a lubrication pump ensures that every lubrication point receives timely and accurate lubrication without stopping production. This capability is especially valuable for customers who prioritize automation, safety, and process stability while aiming to reduce dependence on manual labor.

Ultimately, a lubrication pump solves multiple pain points faced by industrial users, including inconsistent lubrication quality, excessive equipment wear, high maintenance costs, and unpredictable downtime. By providing reliable, automated, and precise lubrication management, it supports safer operation, longer equipment life, and higher productivity. As industries continue to pursue efficiency, sustainability, and intelligent manufacturing, the lubrication pump remains a foundational component that delivers long-term value and competitive advantage.