ZCSLP91-H Lubrication Pump

· On request, an optional external controller can be installed in the cockpit to facilitate the driver to observe the operation of the lubrication system. · Piston pump core contains two different displacement specifications, pressure up to 12MPa, meet 15 meters long-distance delivery. · The lubrication point connector is of quick-plug type, which is easy to install. The special refueling port with strainer ensures that the filled grease is clean and free of impurities. · The lubrication pump, filled with grease, weighs only 3.3kg, small volume, light weight, lightweight design suitable for a variety of scenarios.

Product Categories:

Lubrication Pump

Introduction

ZC91-H lubrication pump uses a brushless synchronous motor to drive the drive shaft and eccentric wheel to rotate and drive the plunger pump core piston rod to reciprocate, so that the pump core can realize the process of sucking and discharging grease. The lubrication pump is small in size, light in weight, high in pressure, long in motor life, point-to-point lubrication, high in protection, CAN communication, and passes EMC.

Keywords:

Features And Benefits

Product advantages: small volume, light weight, high pressure, stable high and low temperature performance, simple system structure, low noise, strong anti-interference ability.

Small volume: external dimensions 182 * 162 * 203, compared with the industry's traditional oil pump volume reduced by 15% to 20%, easy to maintain, easy to arrange, occupies a small space.

Light weight: pump weight 3.3Kg, compared with the industry's traditional oil pump weight reduction of 20% ~ 30%, lightweight design, energy saving and emission reduction.

High pressure: the highest working pressure of 12MPa can be realized, which can meet the 15-meter long-distance grease transmission.

Stable performance in high and low temperatures: it can be filled with No.2 high viscosity grease, with strong adhesion, and the grease is not easy to be lost in high temperature weather, and it has strong pumping ability to meet the requirements of pumping in low temperature of -40℃, and it can be continuously lubricated in low temperature; and it is simple in system structure.

Simple system structure: pumps and lubrication points are directly connected, point-to-point lubrication, without distributor, integrated controller, general CAN communication to realize monitoring;.

Low noise: the use of brushless motors (design life of 12 years), the operating noise is not greater than 30dB, the human ear senseless.

No electromagnetic interference / anti-interference ability: fully meet the “GB/T 17626.2 electromagnetic compatibility test and measurement techniques electrostatic discharge immunity test” and other EMC project requirements, do not interfere with other electrical equipment and not be electromagnetic interference.

| Classification | Function | Parameter |

| Monitoring unit | Rest time | 1~99(min) |

| Working hours | 1~99(min) | |

| Digital Display | Rest time; working time; fault code, etc. | |

| Temperature monitoring | Low temperature protection display | |

| Communication function | Send to CAN bus via CAN message | |

| Alarm function | Motor short circuit, circuit break alarm | |

| Grease supply unit (multi-line pump) | Fuel tank capacity | 1L |

| Motor parameters | 4W AC24V/0.2A 0.45r/min | |

| Pump core specifications | 0.015/0.035(mL/cy) | |

| Output pressure | 10MPa | |

| Applicable grease | NLGI-00、0、1、2 | |

| Lubrication points | 1~19 | |

| Pipeline accessories | Oil distribution pipe | φ4×0.75 Nylon tube |

| Applicable environment | temperature | -40℃~70℃ |

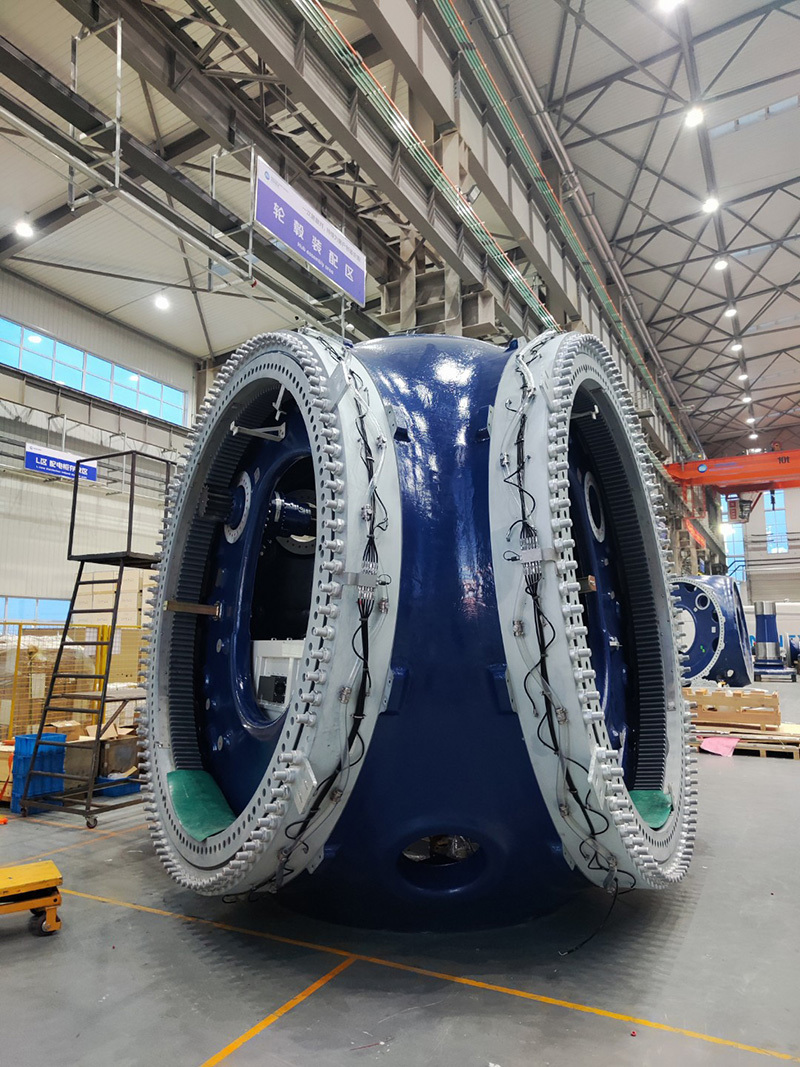

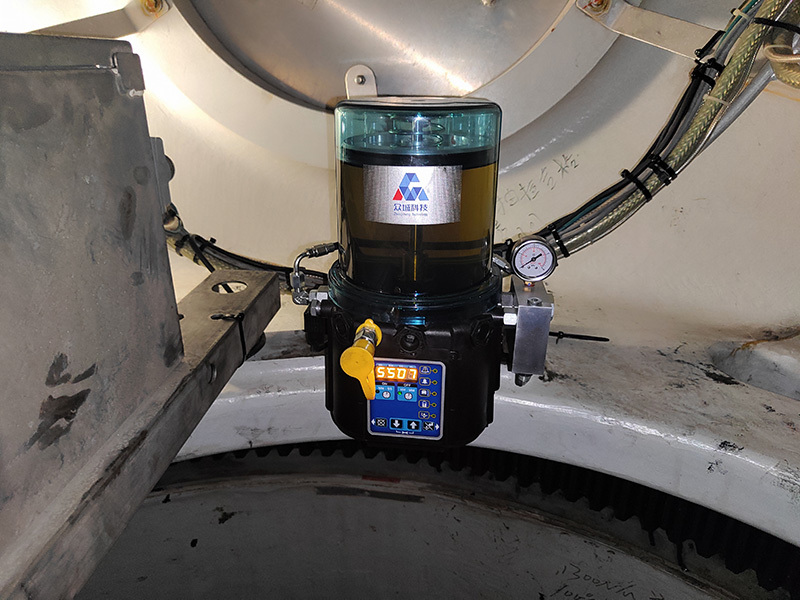

Related Cases

Provide safe and reliable lubrication solutions for global customers

More Products

Provide safe and reliable lubrication solutions for global customers

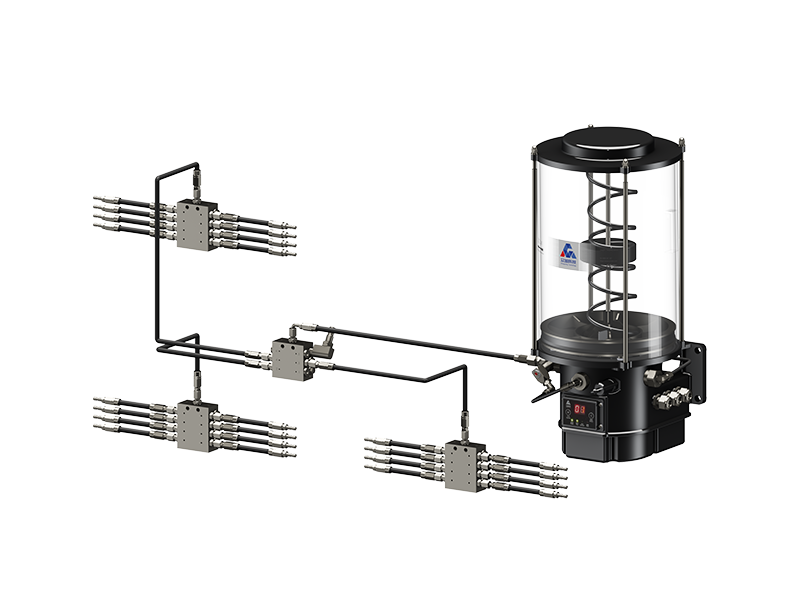

Multi-line plunger lubrication system

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working.

ZC78 Single-Line Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working and the grease is transported to the single-line distributor through the main line.

ZC78 Disc Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

ZC58 Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

Get Exclusive Customized Solutions

Would you like to know more about our products? Please fill out the form. Alternatively, you can send us a detailed list of requirements and we will get back to you within 1 working day.