Pressurized Lubrication System

When the rest countdown ends, the grease supply unit receives the start command from the controller, the motor drives the gear pump to operate, the pressure relief valve opens

Product Categories:

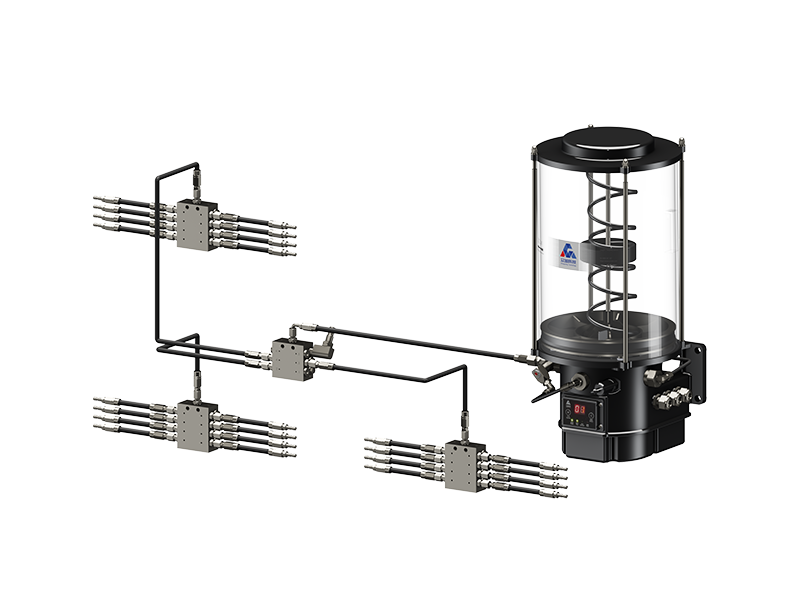

System

Introduction

Working principle

When the rest countdown ends, the grease supply unit receives the start command from the controller, the motor drives the gear pump to operate, the pressure relief valve opens, and the high-pressure grease is transported to the distributor through the main oil pipe, and then discharged to each lubrication point after precise measurement.

Keywords:

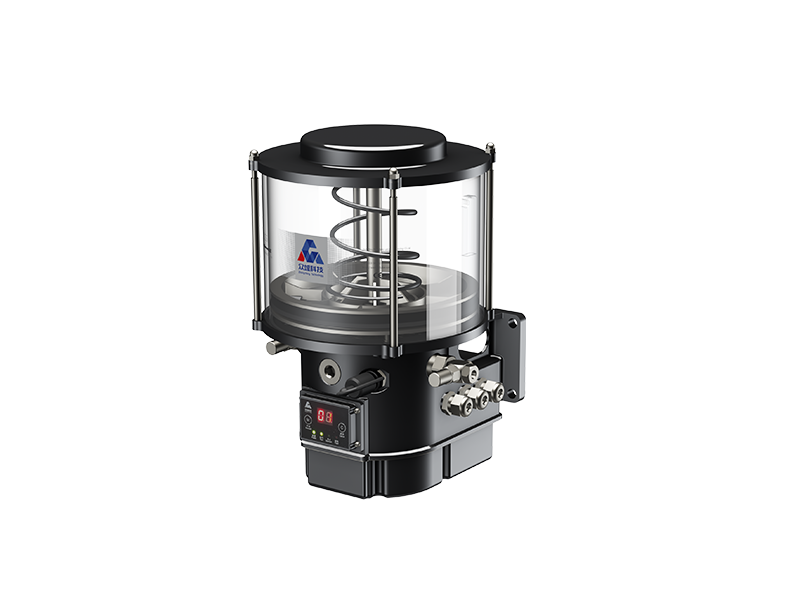

ZC82 Pressurized Lubrication System

Features And Benefits

·High pressure: innovative stirring rod design, up to 8MPa high pressure output, can be filled with 1# grease, grease is not easy to lose in high temperature conditions, and can cope with high cold conditions easily;

·No grease deposition: 360° stirring device at the bottom of the oil tank ensures that there is no dead corner in the oil tank, grease does not deposit, and the grease utilization rate is high;

·Internet of Vehicles: standard CAN communication module, can be connected to the Internet of Vehicles APP, and monitor the lubrication status at any time;

·High-end LCD screen: built-in/external ECU LCD intelligent controller, convenient for observation and adjustment;

·High protection: protection level IP67, no worries in rainy days.

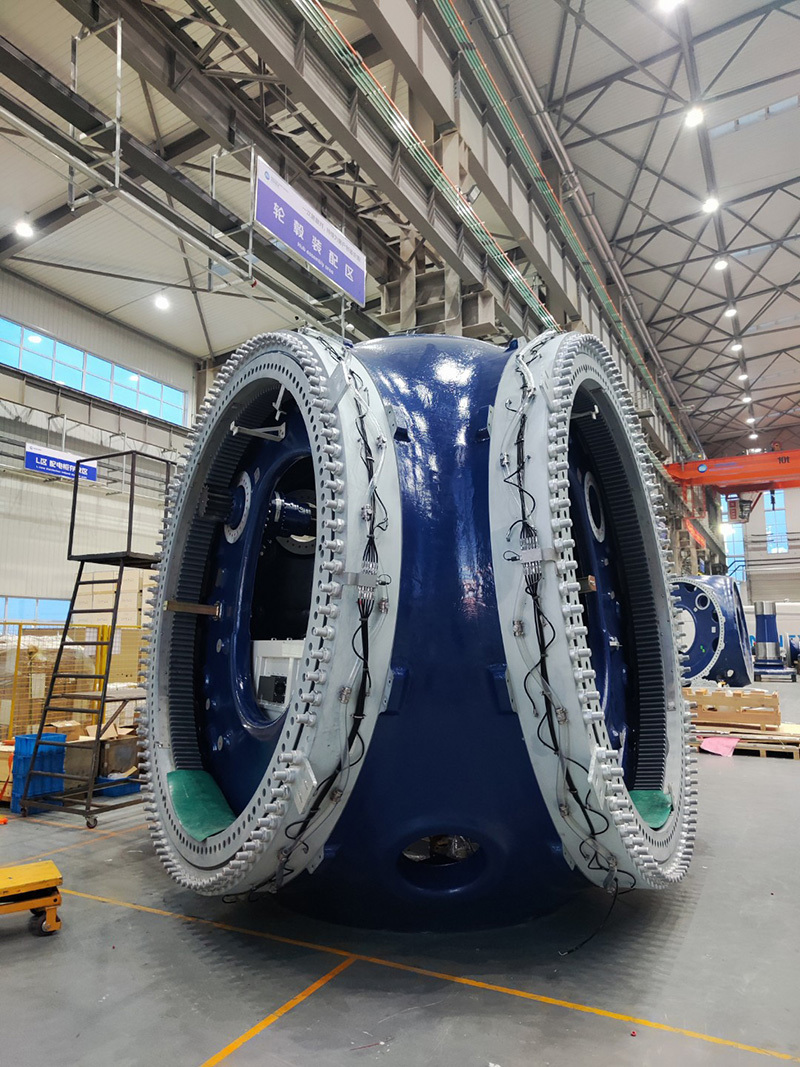

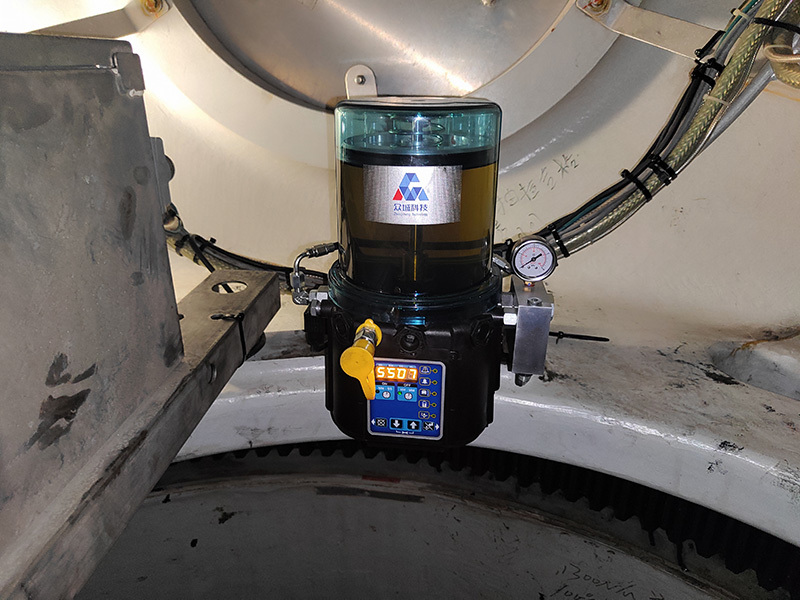

Related Cases

Provide safe and reliable lubrication solutions for global customers

More Products

Provide safe and reliable lubrication solutions for global customers

Multi-line plunger lubrication system

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working.

ZCH78 Disc Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

ZCH58 Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

ZCH55 Platen High Pressure Piston Pump

The C5X series plunger pump consists of a reduction DC motor, a pump core assembly, a safety valve assembly, an eccentric assembly and an oil tank assembly. The controller controls the motor to run, drives the eccentric wheel through the transmission main shaft, and drives the plunger piston rod to reciprocate and pump grease.

Get Exclusive Customized Solutions

Would you like to know more about our products? Please fill out the form. Alternatively, you can send us a detailed list of requirements and we will get back to you within 1 working day.