ZCSLP515 Platen High Pressure Piston Pump

The C5X series plunger pump consists of a reduction DC motor, a pump core assembly, a safety valve assembly, an eccentric assembly and an oil tank assembly. The controller controls the motor to run, drives the eccentric wheel through the transmission main shaft, and drives the plunger piston rod to reciprocate and pump grease.

Product Categories:

Lubrication Pump

Introduction

The C5X series plunger pump consists of a reduction DC motor, a pump core assembly, a safety valve assembly, an eccentric assembly and an oil tank assembly. The controller controls the motor to run, drives the eccentric wheel through the transmission main shaft, and drives the plunger piston rod to reciprocate and pump grease.

Keywords:

Features And Benefits

Excellent performance

Adopts DC permanent magnet reduction motor, with large torque and small current; excellent low temperature performance, stable flow, higher reliability; low noise, working noise <45 decibels.

Stable and reliable

The pump core is made of high-strength alloy steel treated by special process, with precision optimization and improvement, better wear resistance and longer life; the oil pump body is made of high-strength aluminum alloy, light weight and high strength; the solenoid valve and grease are operated in separate chambers, with low failure rate.

Strong environmental adaptability

The protection level of the lubrication pump is IP67; the anti-corrosion performance meets the environmental requirements of onshore and offshore wind power.

| Model | Control Mode | Fuel tank capacity | Pump core flow | Maximum pressure | Power | Voltage | Connectors | Applicable grease | Adapt to temperature | Protection level |

| ZC55 |

Built-in controller External controller |

4L |

2mL/min 2.8mL/min 4mL/min 4.5mL/min 6mL/min |

30MPa 35MPa |

30W |

DC24V AC230V |

Gland Hirschman |

NLGI-0、1、2 | -40~80℃ | IP67 |

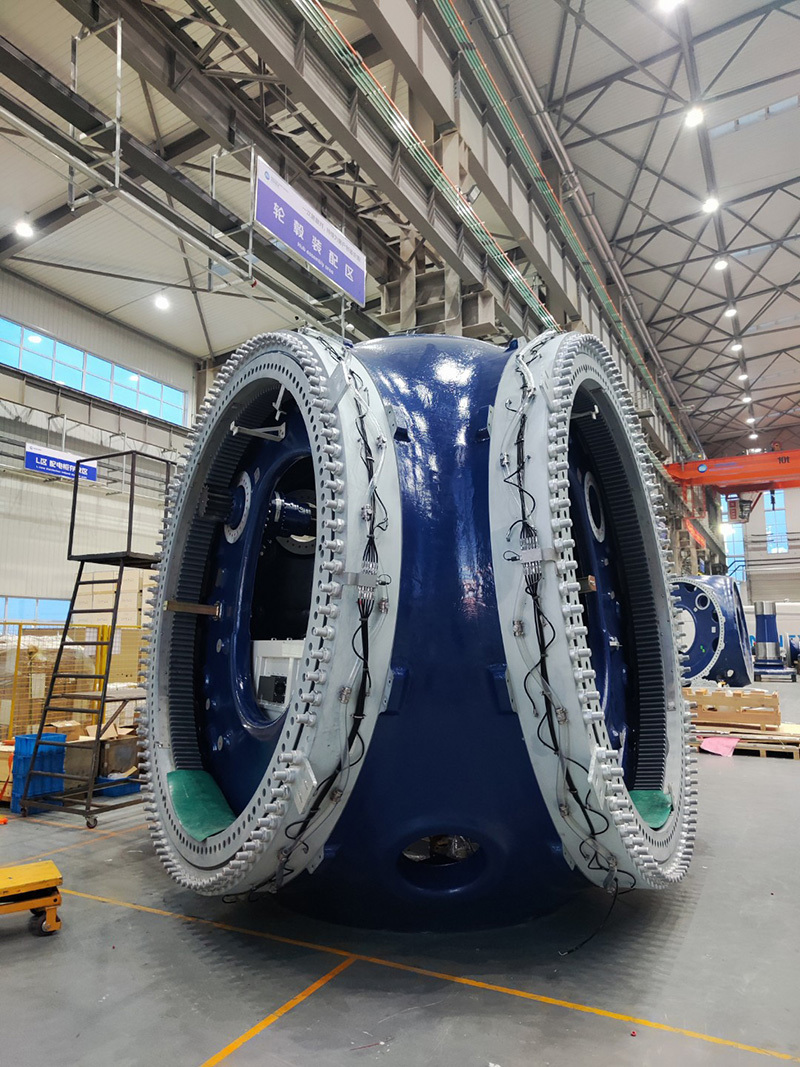

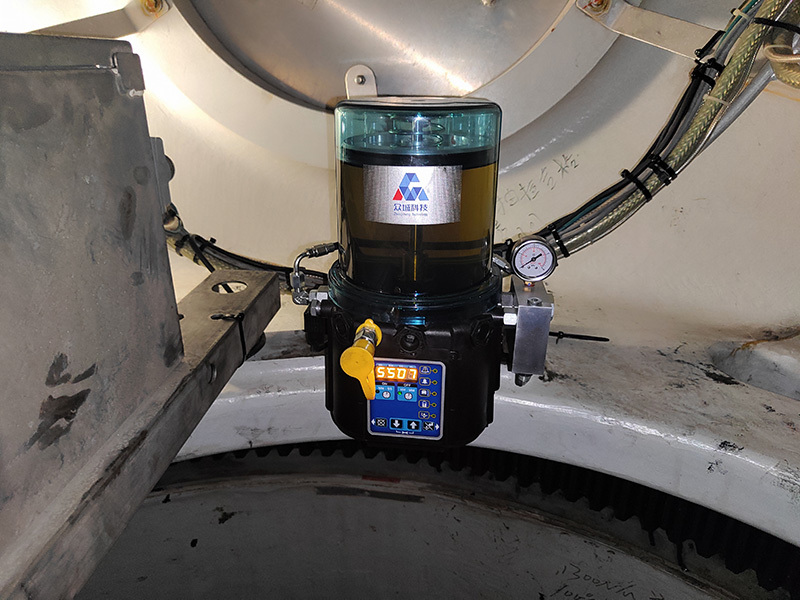

Related Cases

Provide safe and reliable lubrication solutions for global customers

More Products

Provide safe and reliable lubrication solutions for global customers

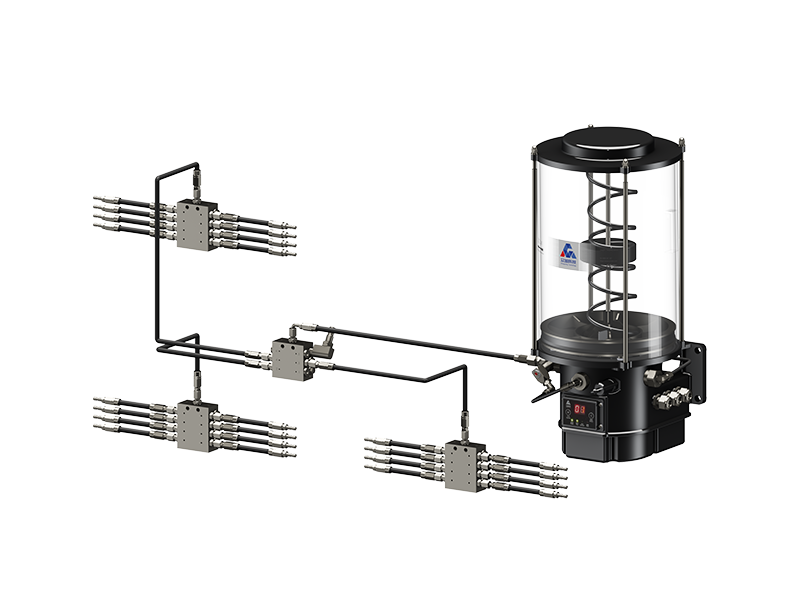

Multi-line plunger lubrication system

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working.

ZC78 Single-Line Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working and the grease is transported to the single-line distributor through the main line.

ZC78 Disc Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

ZC58 Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

Get Exclusive Customized Solutions

Would you like to know more about our products? Please fill out the form. Alternatively, you can send us a detailed list of requirements and we will get back to you within 1 working day.