ZL9XPro+ Series Precision Filtration System

The ZL9XPro+ series precision filtration system consists of a motor pump, a control box, a filter cartridge, a filter element, an oil sensor, a temperature sensor, a pressure switch, a pressure gauge, and pipeline accessories. Online bypass filtration has high filtration accuracy (3μm) and can filter a variety of pollutants (metal particles in the oil, oil degradation products, water, etc.)

Product Categories:

Filtration System

Introduction

The ZL9XPro+ series precision filtration system consists of a motor pump, a control box, a filter cartridge, a filter element, an oil sensor, a temperature sensor, a pressure switch, a pressure gauge, and pipeline accessories. Online bypass filtration has high filtration accuracy (3μm) and can filter a variety of pollutants (metal particles in the oil, oil degradation products, water, etc.)

The motor pump circulates the lubricating oil in the gearbox through the filtration system to filter out insoluble particles, oil degradation products, water and other oil pollutants in the oil, thereby improving the quality of the oil, increasing the utilization rate of the oil, extending the service life of the equipment, and creating greater value for customers.

During the oil filtration process, the oil testing equipment quickly and accurately performs real-time quality testing on the customer's system oil, and transmits the test results to the control system.

The control system transmits the oil test results to the customer, grasps the oil cleanliness status in real time, and controls the system operation according to the oil status to ensure that the oil meets the system use requirements.

Keywords:

Features And Benefits

Online bypass filtration

Does not affect equipment operation, improves power generation efficiency, and ensures oil performance and service life

High filtration accuracy and filtration efficiency

Select high-precision filter elements with a filtration accuracy of 3μm and high one-time interception efficiency

High dirt holding capacity and wide range of filtration media

The dirt holding capacity is 5-10 times that of system filtration; it can not only filter metal particles and grinding chips, but also filter

Water, oil degradation products, sludge and other impurities in the oil

Wide range of applicable oil products

Can filter oil in the viscosity range of 32cst to 320cst

High safety

Equipped with filter element blockage, motor overload, and other sensor alarm devices, equipment failure status is discovered and handled in time; the system adopts an integrated oil circuit with low risk of oil leakage

Easy to install

Compact structure, small size, easy to install

Real-time monitoring of oil quality

Can be equipped with oil cleanliness monitoring device, real-time monitoring of oil quality, and accurate formulation of oil change period

Convenient observation of working status

Equipped with intelligent control and display system, the equipment operation status is clear and intuitive

| Dimensions | 430×435×477 |

| Rated voltage | 220/380/690V AC |

| Design pressure | 12 bar |

| Rated flow | 60 L/h,120L/h,240L/h |

| Filtration accuracy | 3 μm |

| Pollution holding capacity | 4.0Kg |

| Water absorption | 2.0Kg |

| Filter replacement pressure | 3 bar |

| Operating temperature | 0℃-70℃ |

| Storage temperature | -40℃-80℃ |

| Use oil viscosity range | ≤320 CST |

| Overvoltage protection | Switching signal |

| Temperature protection | Analog signal |

| Pollution/Moisture Sensors | 485 communication, CAN communication |

| Wear Debris Sensor | 485 communication, CAN communication |

| Viscosity Sensor | 485 communication, CAN communication |

| Flow Meter | Pulse signal |

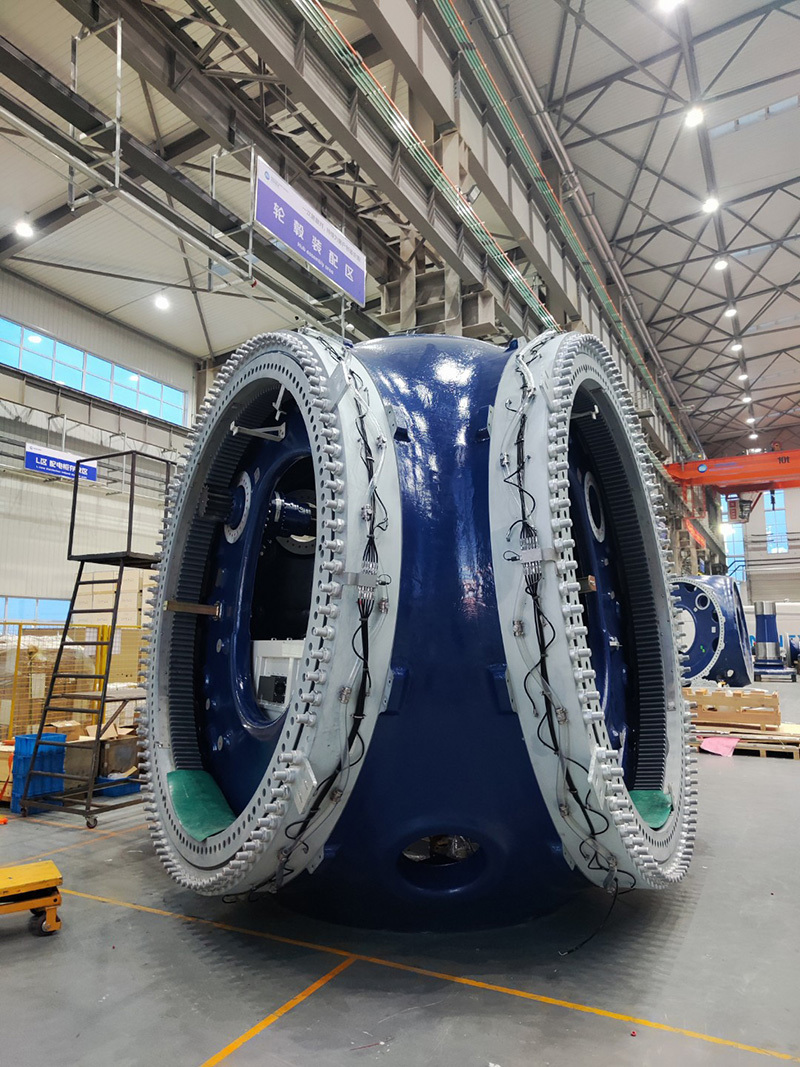

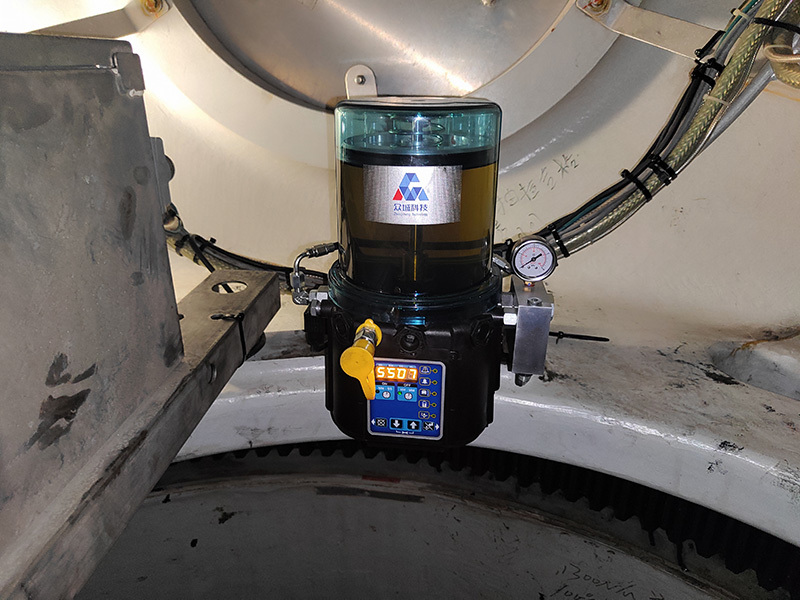

Related Cases

Provide safe and reliable lubrication solutions for global customers

More Products

Provide safe and reliable lubrication solutions for global customers

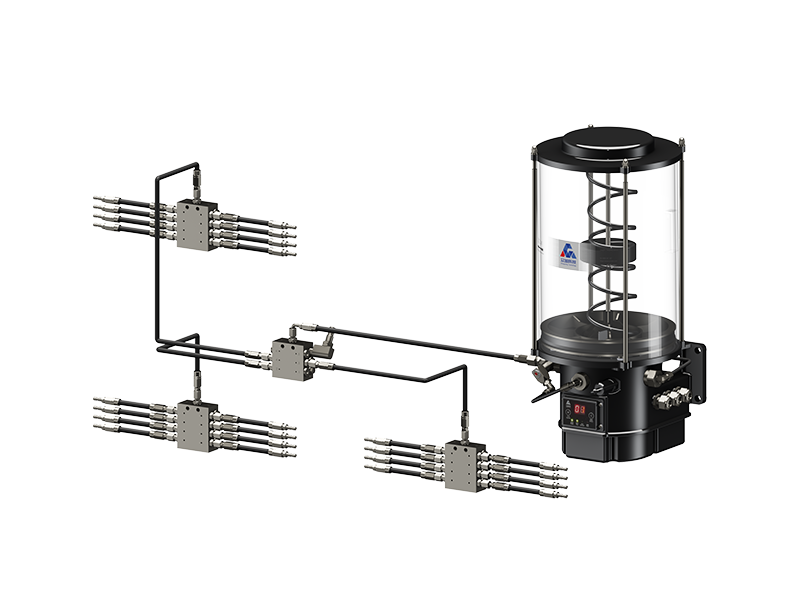

Multi-line plunger lubrication system

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working.

ZCH78 Disc Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

ZCH58 Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

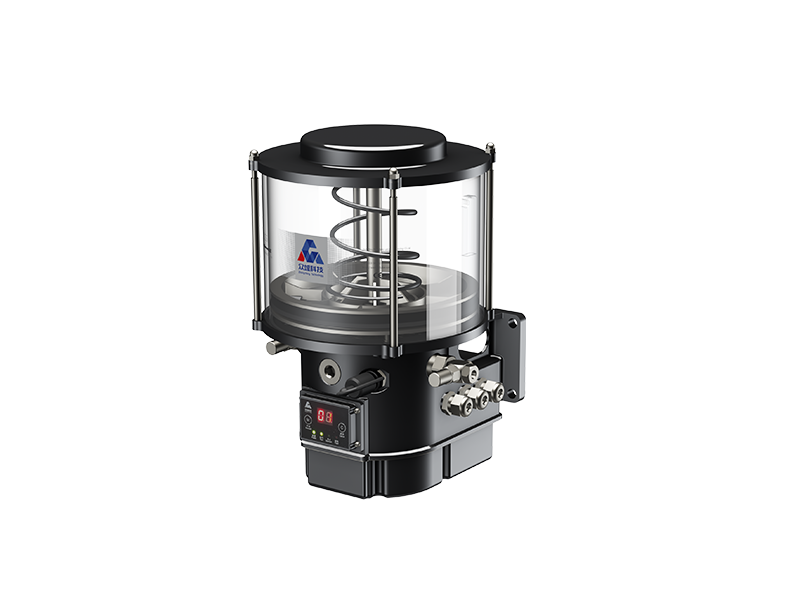

ZCH55 Platen High Pressure Piston Pump

The C5X series plunger pump consists of a reduction DC motor, a pump core assembly, a safety valve assembly, an eccentric assembly and an oil tank assembly. The controller controls the motor to run, drives the eccentric wheel through the transmission main shaft, and drives the plunger piston rod to reciprocate and pump grease.

Get Exclusive Customized Solutions

Would you like to know more about our products? Please fill out the form. Alternatively, you can send us a detailed list of requirements and we will get back to you within 1 working day.