Lubricate The Pinion

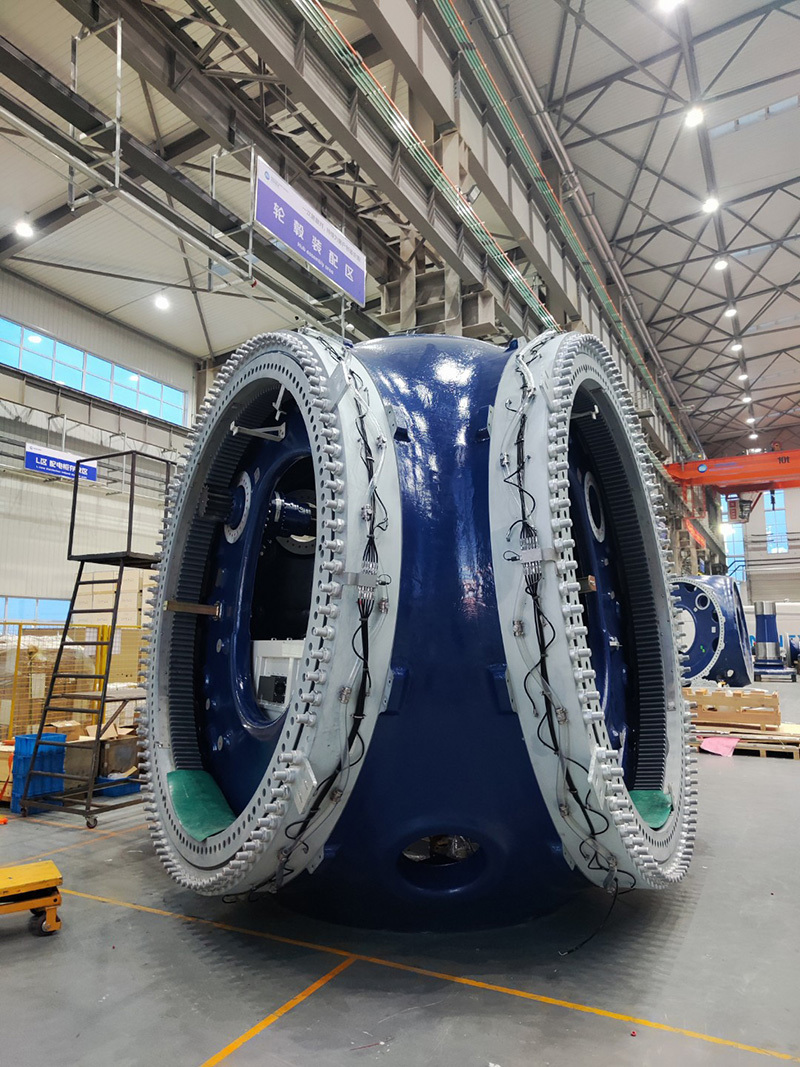

The lubricating pinion is composed of gears, shafts, seals, retaining rings, fasteners, etc.

Product Categories:

Attachment

Introduction

The lubricating pinion is composed of gears, shafts, seals, retaining rings, fasteners, etc.

The gears are modularly designed and adopt a piece-type assembly structure, which makes the gear width flexible and optional; the gears can achieve directional grease discharge through the internal structure.

Keywords:

Features And Benefits

·The base body is made of thermoplastic polyurethane rubber (TPU) material, which is light in weight, strong in wear resistance, and has excellent comprehensive properties such as high strength, high toughness, wear resistance, and oil resistance, and has good processing performance

·Flake structure, modular design, can adapt to tooth surfaces of different widths

·Tooth surface contact, with oil storage tank, directional oil supply, no grease splashing, more accurate and efficient lubrication

·Multi-layer oil discharge on the tooth surface, wide lubrication surface, more sufficient lubrication

| Technical Parameters | Material | Operating temperature | Corrosion resistance | Gear module | Gear Width/Mounting Bracket |

| Thermoplastic polyurethane rubber(TPU) | -40℃~80℃ | C4H | 8/10/12/14/16/20/22/24/26 | Customized according to customer needs |

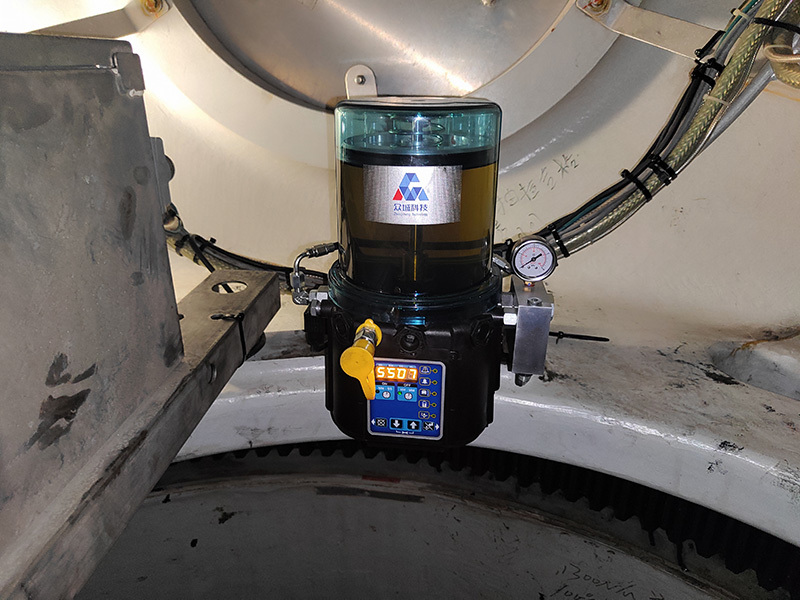

Related Cases

Provide safe and reliable lubrication solutions for global customers

More Products

Provide safe and reliable lubrication solutions for global customers

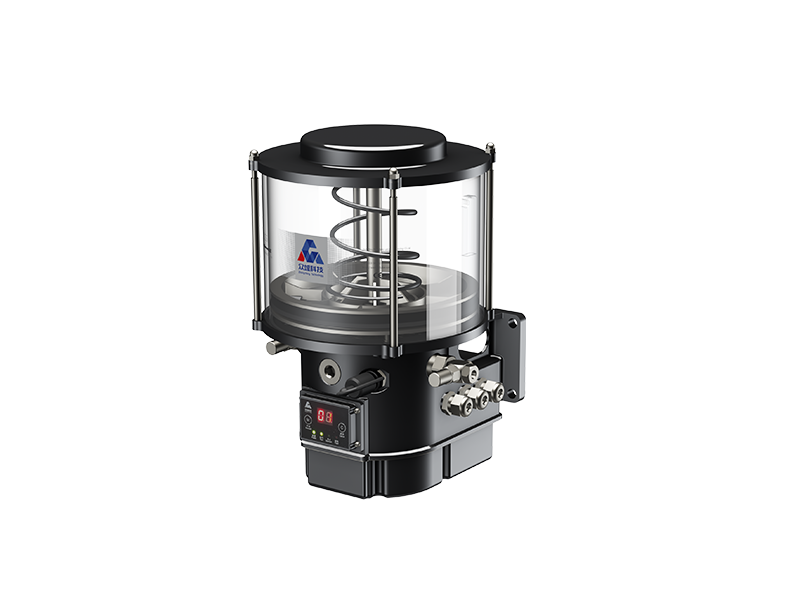

Multi-line plunger lubrication system

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working.

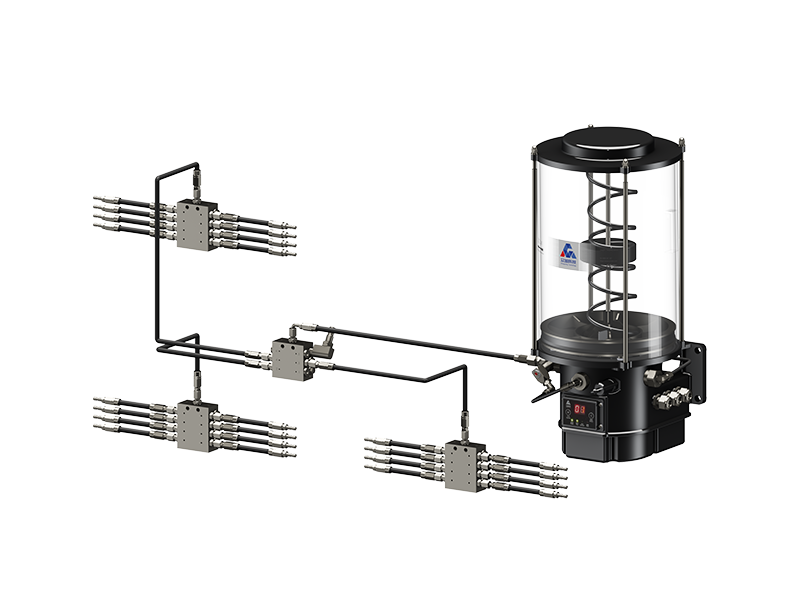

ZCH78 Disc Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

ZCH58 Progressive Lubrication System

Run according to the preset program. When the rest countdown ends, the lubrication pump starts working, and the grease is transported to the progressive distributor through the main pipeline.

ZCH55 Platen High Pressure Piston Pump

The C5X series plunger pump consists of a reduction DC motor, a pump core assembly, a safety valve assembly, an eccentric assembly and an oil tank assembly. The controller controls the motor to run, drives the eccentric wheel through the transmission main shaft, and drives the plunger piston rod to reciprocate and pump grease.

Get Exclusive Customized Solutions

Would you like to know more about our products? Please fill out the form. Alternatively, you can send us a detailed list of requirements and we will get back to you within 1 working day.