Top Advantages of Using Platen High Pressure Piston Pumps in Electric Equipment

Top Advantages of Using Platen High Pressure Piston Pumps in Electric Equipment

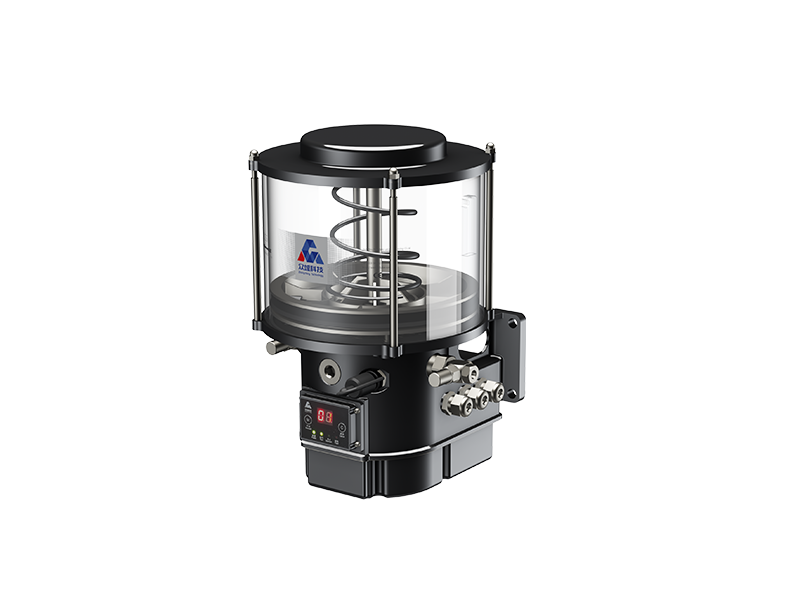

Introduction to Platen High Pressure Piston Pumps

In the ever-evolving landscape of electric equipment and power generation, the choice of pumping solutions plays a crucial role in optimizing efficiency and performance. Among the various options available, **platen high pressure piston pumps** stand out for their rem

Top Advantages of Using Platen High Pressure Piston Pumps in Electric Equipment

Introduction to Platen High Pressure Piston Pumps

In the ever-evolving landscape of electric equipment and power generation, the choice of pumping solutions plays a crucial role in optimizing efficiency and performance. Among the various options available, **platen high pressure piston pumps** stand out for their remarkable capabilities. Whether used in power generation or other electric equipment, these pumps offer unparalleled advantages that can significantly enhance operational effectiveness.

Why Choose Platen High Pressure Piston Pumps?

**Platen high pressure piston pumps** are engineered for high efficiency and reliability. Their unique design allows for precise fluid handling, which is essential in various electric equipment applications. Here, we delve into the numerous advantages these pumps bring to the table, making them a top choice for engineers and manufacturers alike.

1. Exceptional Pressure Generation

One of the primary benefits of **platen high pressure piston pumps** is their ability to generate high pressure. They can operate at significantly higher pressures compared to standard pumps, making them ideal for applications that require substantial force to move fluids. This capability ensures that operations are not only effective but also efficient, minimizing energy wastage.

2. Enhanced Operational Efficiency

Operational efficiency is paramount in electric equipment. Platen high pressure piston pumps are designed to maximize fluid output while minimizing energy consumption. Their construction allows for reduced friction losses and improved sealing, leading to a greater volume of fluid being moved per unit of energy expended. This efficiency translates into lower operational costs and increased profitability.

3. Versatility Across Applications

These pumps are incredibly versatile, finding applications in various sectors, including hydraulic systems, cooling systems, and industrial processes. Their adaptability to different fluid types and operating conditions makes them an essential component in many electric equipment setups. Whether dealing with viscous fluids or low-viscosity liquids, platen high pressure piston pumps can handle it all.

4. Robust Construction and Reliability

Durability is another hallmark of platen high pressure piston pumps. Their robust construction allows them to withstand harsh operating conditions, including high temperatures and corrosive environments. This reliability ensures that they can operate efficiently over extended periods without significant maintenance, reducing downtime and enhancing overall productivity.

Corrosion Resistance

Many **platen high pressure piston pumps** are constructed with materials that provide excellent corrosion resistance. This attribute is particularly beneficial in electric equipment that operates in environments where exposure to corrosive substances is likely. As a result, these pumps can maintain their performance and longevity even in challenging conditions.

5. Low Maintenance Requirements

Maintenance can be a significant cost factor in the operation of electric equipment. Fortunately, platen high pressure piston pumps are designed with low maintenance in mind. Their robust design and efficient operation mean that they require less frequent servicing compared to traditional pumps. This not only helps to reduce maintenance costs but also allows operators to focus on other critical aspects of their operations.

Easy Troubleshooting

The design of these pumps often includes intuitive features that make troubleshooting easier. With fewer moving parts and a straightforward assembly, identifying issues and performing repairs can be accomplished quickly, minimizing downtime.

6. Improved Energy Efficiency

In today's environmentally conscious world, energy efficiency is a vital consideration. Platen high pressure piston pumps excel in this area, consuming less power while delivering optimal performance. This characteristic helps organizations reduce their carbon footprint and aligns with sustainability goals. The use of energy-efficient pumps can significantly decrease electricity costs, making them an attractive option for electric equipment manufacturers and operators.

Eco-Friendly Operation

The reduced energy consumption not only lowers operational costs but also promotes eco-friendly practices. By utilizing pumps that consume less energy, businesses can contribute to a more sustainable future while maintaining competitive operational standards.

7. Precision Fluid Control

Precision is critical in many electric equipment operations. Platen high pressure piston pumps allow for precise control over the flow rate and pressure of the fluid being pumped. This capability is particularly important in applications where exact measurements are required, ensuring that operations run smoothly and efficiently.

Integration with Automation Systems

Many modern platen high pressure piston pumps can easily integrate with automation systems, allowing for real-time monitoring and control. This integration enhances operational efficiency and provides valuable data for optimizing processes.

8. Cost-Effectiveness in the Long Term

While the initial investment in **platen high pressure piston pumps** may be higher compared to traditional pumping solutions, the long-term cost-effectiveness cannot be overlooked. The combination of low maintenance needs, energy efficiency, and durability results in significant savings over time. Organizations are increasingly recognizing the value of investing in high-quality pumps that provide superior performance and reliability.

Applications of Platen High Pressure Piston Pumps in Electric Equipment

Understanding the various applications of platen high pressure piston pumps helps in appreciating their versatility and benefits further. Here, we explore some key areas where these pumps are commonly used.

1. Hydraulic Systems

In hydraulic systems, platen high pressure piston pumps are essential for generating the necessary pressure to operate hydraulic machinery and equipment. Their efficiency and reliability make them ideal for construction machinery, automotive applications, and manufacturing processes.

2. Cooling Systems

Cooling systems in electric equipment often require precise fluid delivery and temperature control. Platen high pressure piston pumps can efficiently circulate coolant fluids, ensuring optimal operating temperatures for sensitive components. This capability helps prevent overheating and extends the lifespan of electric equipment.

3. Power Generation

In the realm of power generation, these pumps play a vital role in various processes, including fuel injection and lubrication. Their ability to operate under high pressures ensures the efficient functioning of systems that rely on precise fluid handling.

4. Industrial Processes

Many industrial processes depend on the reliable movement of fluids. Platen high pressure piston pumps are utilized across multiple industries, including chemical processing, food and beverage production, and pharmaceuticals, to ensure the smooth flow of materials.

Conclusion

In conclusion, the **advantages of using platen high pressure piston pumps** in electric equipment are numerous and compelling. From exceptional pressure generation and operational efficiency to low maintenance needs and long-term cost-effectiveness, these pumps provide unparalleled benefits that enhance the performance of electric equipment across various applications. Their robust construction and versatility ensure that they remain a top choice for engineers and manufacturers aiming to optimize their operations. As industries continue to evolve, the adoption of platen high pressure piston pumps will undoubtedly play a significant role in shaping the future of electric equipment and power generation.

Frequently Asked Questions (FAQs)

1. What are platen high pressure piston pumps used for?

Platen high pressure piston pumps are primarily used in hydraulic systems, cooling systems, power generation, and various industrial processes that require precise fluid handling.

2. How do platen high pressure piston pumps work?

These pumps operate using a piston mechanism that generates high pressure by moving fluid through a cylinder. The design allows for efficient fluid transfer with minimal energy loss.

3. What are the benefits of using these pumps over traditional pumps?

The benefits include higher pressure capabilities, enhanced operational efficiency, reduced maintenance requirements, and improved energy efficiency, leading to cost savings in the long run.

4. Are platen high pressure piston pumps suitable for corrosive fluids?

Yes, many platen high pressure piston pumps are designed with materials that provide excellent corrosion resistance, making them suitable for handling corrosive fluids.

5. How do I choose the right platen high pressure piston pump for my application?

Choosing the right pump depends on factors such as the required pressure, fluid type, desired flow rate, and specific operating conditions. Consulting with manufacturers or experts can help identify the best option for your needs.

Previous